HDPE Liner Price

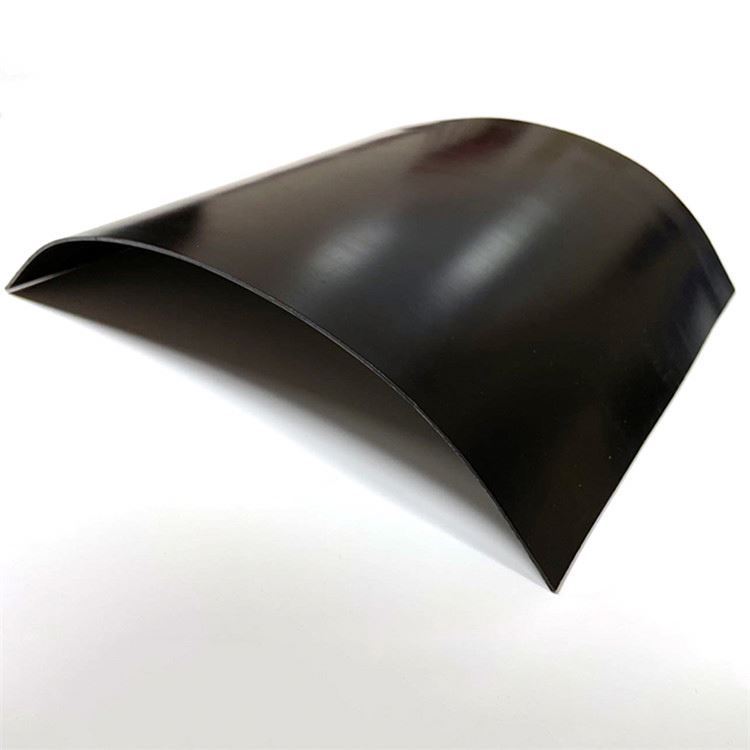

HDPE Liner refers to a smooth, high-quality waterproof liner made from specially formulated virgin polyethylene resin. This resin is specifically developed for flexible geomembrane applications. The pond liner plastic sheet is composed of approximately 97.5% polyethylene, 2.5% carbon black, and small amounts of antioxidants and heat stabilizers. No additional additives, fillers, or extenders are used, ensuring excellent purity, durability, and performance.

Excellent Chemical Resistance – Resistant to a broad range of acids, alkalis, and industrial chemicals.

High Durability – Exceptional aging and weather resistance deliver a long-lasting service life.

Superior Flexibility – Easily conforms to uneven surfaces and complex structures for smooth installation.

Outstanding Impermeability – Ensures effective leakage prevention and strong environmental protection.

Versatile Applications – Ideal for use in landfills, ponds, reservoirs, and various containment and waterproofing projects.

HDPE Liner is a kind of smooth, high quality waterproof liner, which is made of specially formulated original polyethylene resin. This raw material is specially designed for flexible geomembrane applications. The pond liner plastic sheeting contains about 97.5% polyethylene, 2.5% carbon black and traces of antioxidants and heat stabilizers. It does not use other additives, fillers or extenders.

Specification

Thickness | 0.2mm ~ 3.0mm |

Roll width | 1m ~ 8m |

Roll length | 30m ~ 420m |

Raw material | virgin high density polyethylene |

Color | black, blue, green, white |

Surface | smooth surfaces, single surface textured, dual surfaces textured |

Main Features | UV resistance, high tearing resistance, puncture-resisting, waterproofing |

S/N | Item | Index | ||||||

Thickness mm | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 | |

1 | Density g/cm3 | ≥0.940 | ||||||

2 | Tensile yield strength (vertical and horizontal) N/mm | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 |

3 | Tensile breaking strength (vertical and horizontal) N/mm | ≥20 | ≥27 | ≥33 | ≥40 | ≥53 | ≥67 | ≥80 |

4 | Elongation (vertical and horizontal) % | - | - | - | ≥12 | |||

5 | Elongation at break (vertical and horizontal) % | ≥700 | ||||||

6 | Tearing load at right angle (vertical and horizontal) N | ≥93 | ≥125 | ≥160 | ≥190 | ≥250 | ≥315 | ≥375 |

7 | Anti-puncture strength N | ≥240 | ≥320 | ≥400 | ≥480 | ≥540 | ≥800 | ≥960 |

8 ' | Tensile load stress cracking (tensile method of dead load of the cut) h | _ | ≥300 | |||||

9 | Carbon black content % | 2.0~3.0 | ||||||

10 | Carbon black dispersion | The number of Level 3 among 10 data is not more than one; Level 4 and Level 5 are not allowed. | ||||||

Oxidation induction time (OIT) min | Oxidation induction time under normal pressure ≥100 | |||||||

11* | Oxidation induction time under disjoining pressure ≥400 | |||||||

12 | 85°C thermal aging (retention rate of OIT under normal pressure after 90d) % | ≥55 | ||||||

13a | Ultraviolet resistance (retention rate of OIT after 1600h ultraviolet irradiation) | ≥50 | ||||||

Note: Technical performance index of thickness specification not listed in the table shall be implemented according to interpolation method. | ||||||||

For two indexes of Item 11 and Item 13, select one from retention rate of OIT under normal pressure and retention rate of OIT under high pressure and carry out the test. | ||||||||

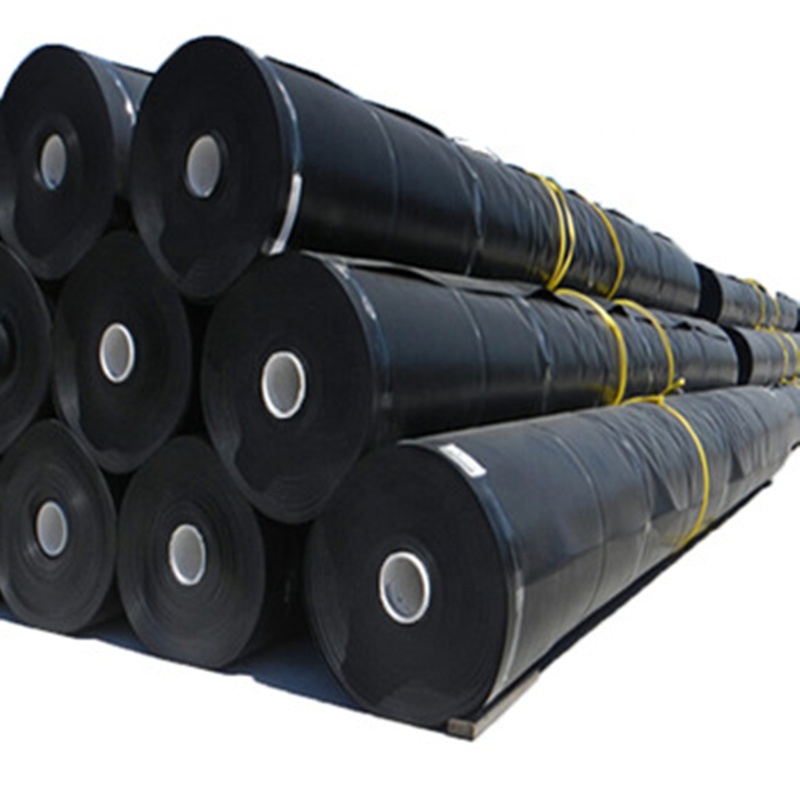

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided. Delivery time: 5-7 working days after receiving deposit payment Rolls size: the width and length can be customized to facilitate container loading, each roll with two lifting belts Packing: Roll with pipe in core; double layers UV stable woven bags

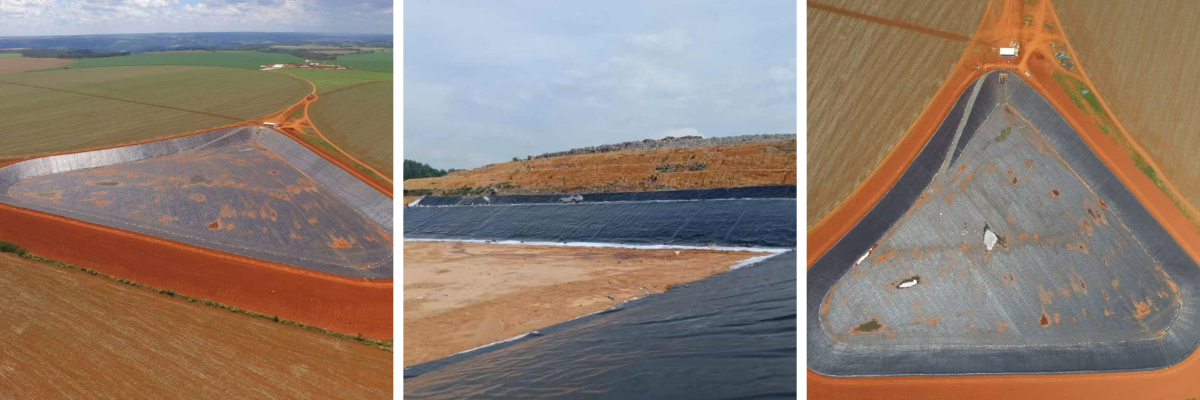

Product Application

(1) Environmental protection and sanitation projects (such as domestic waste landfills, sewage treatment plants, workshops)

(2) Water conservancy and civil engineering (river/lake/reservoir/dike anti-seepage, plugging, reinforcement)

(3) Municipal engineering (underground, underground construction of buildings and roof tanks, lining of sewage pipes)

(4) Landscaping (artificial lake, pond, pond lining of golf course)

(5) Petrochemical (chemical plant, oil refinery storage tank anti-seepage and anti-fouling, chemical reaction tank lining)

(6) Mining (washing pond, heap leaching pond, ash dump)

(7) Traffic engineering (highway foundation reinforcement, culvert seepage prevention)

(8) Agriculture (reservoir, reference basin, storage tank, anti-seepage of irrigation system)

(9) Aquaculture (lining of fish ponds, shrimp ponds)

(10) Polluting enterprises (phosphorite enterprises, sugar factories)

FAQ

1. Where is our company located ?

Economic Development Zone, Ling County, Dezhou City, Shandong Province. China.

2. Can you send samples to us ?

Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

3. What's your Payment term ?

T/T , L/C , Western Union.

4. What's your delivery method ?

By sea , By train , By ari, depend on your country.