geomembrane liner cost

Industry-Leading Impermeability

Reinforced Durability & Strength

Sustainable & Regulatory Compliance

Cost-Efficient Installation

ll-Climate Reliability

1. Introduction

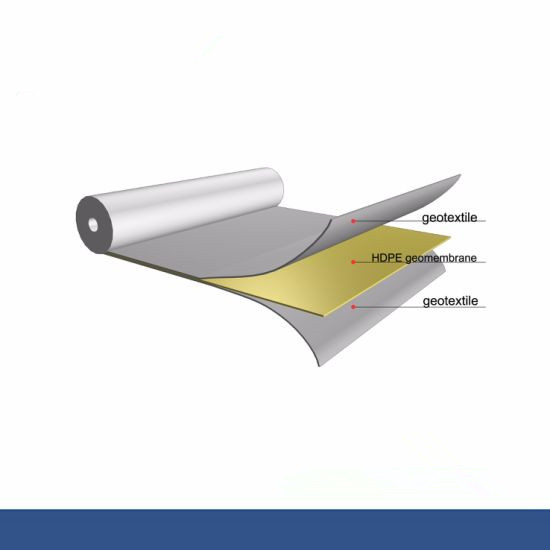

Composite geomembrane—often referred to as "geocomposite liner" in global engineering circles—is a premium integrated geosynthetic solution engineered by bonding impermeable geomembrane layers (HDPE, LLDPE, or PVC as primary substrates) with reinforcing non-woven/woven geotextiles (polypropylene/polyester) via advanced thermal lamination, adhesive bonding, or needle-punch technology. It merges the barrier performance of geomembranes with the structural strength, filtration, and protective capabilities of geotextiles, delivering a all-in-one solution that meets the rigorous demands of international infrastructure, environmental, and industrial projects. Compliant with globally recognized standards (ASTM D751, EN 13763, ISO 10713), it has become the go-to choice for engineers, contractors, and project owners worldwide—trusted for its reliability across diverse climates and critical applications.

2. Core Advantages (Globally Valued Performance)

• Industry-Leading Impermeability: Features ultra-low permeability (≤1×10⁻¹⁰ m/s for HDPE-based composites), exceeding the seepage control requirements of strict environmental regulations (e.g., EU Landfill Directive, US EPA, Australian EPA) for containing leachate, chemicals, and groundwater.

• Reinforced Durability & Strength: The geotextile layer enhances tensile strength (≥25 kN/m), tear resistance, and puncture protection—shielding the inner membrane from construction damage (e.g., sharp soil particles, heavy equipment) and extending service life to 50+ years in typical applications, aligning with long-term infrastructure goals.

• ll-Climate Reliability: Performs flawlessly in extreme conditions—maintaining flexibility in sub-zero temperatures (-30°C) for Nordic and Canadian projects, and thermal stability in scorching Middle Eastern/Australian deserts (up to 60°C) without cracking or brittleness.

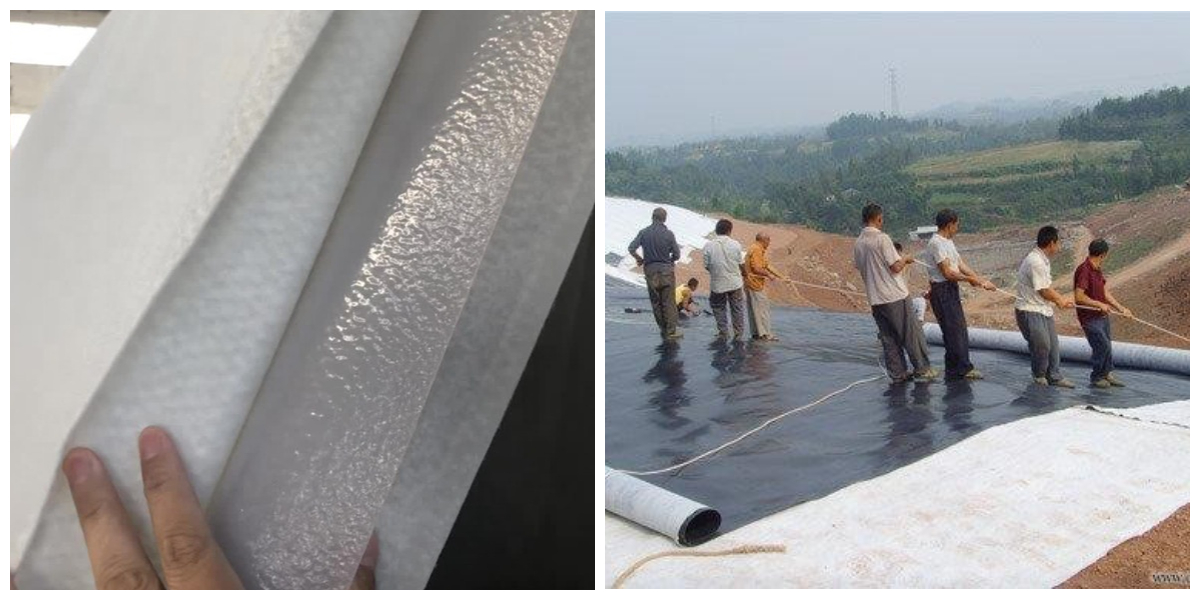

• Cost-Efficient Installation: Lightweight (3–8 kg/m²) and easy to handle, with compatibility for hot-air welding (for thermoplastics) to create seamless joints. Adapts to uneven substrates, reducing site preparation costs— a key advantage for projects in developing markets with less refined construction sites.

• Sustainable & Regulatory Compliance: Crafted with low-VOC, recyclable materials, it aligns with global sustainability initiatives (EU Green Deal, US LEED, ISO 14001). Meets safety standards for potable water contact (FDA, EU Drinking Water Directive) and eco-sensitive applications like wetland restoration.

3. Global Key Applications (Region-Specific Use Cases)

• Environmental Protection: Landfill liners and capping systems (Europe’s brownfield redevelopment, US municipal waste sites, Asian industrial landfill projects) to prevent soil/groundwater contamination; mine tailing pond liners (Australian coal mines, South American lithium mines) and contaminated site remediation.

• Water Resources Management: Reservoir, canal, and irrigation liners (water-scarce regions: American Southwest, Middle East, North Africa) for water conservation; flood control barriers (European coastal defense, Southeast Asian monsoon-prone areas) and coastal reclamation projects (Dubai, Singapore).

• Civil Infrastructure: Tunnel and subway waterproofing (Tokyo Metro, London Crossrail, Dubai’s underground networks); road and railway subgrade barriers (North American highways, European high-speed rail) to control groundwater seepage and enhance structural stability.

• Industrial & Energy Projects: Chemical storage tank secondary containment (EU/US refineries), oil/gas pipeline bedding (Russian Arctic pipelines), and renewable energy facilities (solar farm site liners, European biogas digesters) for leak prevention.

• Agriculture & Aquaculture: High-yield fish pond liners (Norway, Chile’s salmon farms), shrimp farm barriers (Southeast Asia), and irrigation channel liners (India, Africa) to minimize water loss and improve crop/aquatic productivity.

4. International Manufacturing Process (Adhering to Global Standards)

1. Global Sourcing & Raw Material QA: High-grade resins (HDPE from EU/US suppliers, LLDPE from Middle Eastern producers) and geotextiles are sourced for consistent quality, with strict testing for purity, UV resistance, and mechanical properties—ensuring compliance with regional material standards.

2. Geomembrane Extrusion: Resins are melted at 180–220°C, extruded through precision T-dies, and cooled via water-cooled rollers to form uniform membrane sheets (0.3–3.0 mm thickness)—a process optimized in European and North American manufacturing facilities for precision.

3. Geotextile Preparation: Non-woven/woven geotextiles undergo pre-treatment (corona or plasma) to enhance bonding adhesion, then inspected for gram weight (100–400 g/m²) and tensile strength to match project-specific requirements (e.g., higher strength for heavy-load infrastructure in North America).

4. Advanced Lamination: Layers are bonded via thermal lamination (most common in global production) or eco-friendly high-strength adhesives (for specialized PVC composites), with full-surface bonding ensured by computer-controlled pressure and temperature—eliminating bubbles or delamination.

5. Quality Control (Global Compliance): Third-party labs (SGS, Intertek, Bureau Veritas) conduct rigorous testing: permeability, peel strength (≥1.5 N/mm), tensile strength, and UV aging resistance—validating compliance with ASTM (US), EN (EU), and JIS (Japan) standards. Test reports are included with each shipment for customs clearance and client acceptance.

6. Packaging & Global Logistics: Finished rolls (standard widths: 3–8m, lengths: 50–100m) are wrapped in UV-resistant, moisture-proof packaging to withstand long sea freight. Each roll is labeled with batch numbers, certifications, and technical specs—facilitating traceability for projects worldwide.