Best Geomembrane Sheet

Best Geomembrane Sheet is a black, high-quality, high-density polyethylene (HDPE) geomembrane made from specially formulated virgin polyethylene resin.

Premium Raw Materials: Produced using 100% virgin polyethylene resin, ensuring exceptional purity, uniformity, and consistent performance.

Excellent Weather Resistance: Reinforced with carbon black and antioxidants for superior UV and thermal aging resistance, making it ideal for long-term exposed applications.

Superior Mechanical Strength: Offers outstanding dimensional stability, high tensile strength, and superior puncture resistance to ensure long-lasting performance.

Environmentally Friendly & Safe: Contains no harmful additives and features excellent chemical stability, making it suitable for a wide range of environmental and containment applications.

International Quality Standards: Fully compliant with GM13 specifications, guaranteeing dependable quality and global acceptance.

Versatile Applications: Widely used in landfills, reservoirs, mining operations, and various environmental protection and water containment projects.

Best Geomembrane Sheets are the ideal choice for a wide range of lining applications. These sheets offer excellent resistance to various solvents and are the most commonly used geomembrane liners worldwide. While HDPE geomembranes are less flexible than LLDPE, they deliver greater tensile strength and superior temperature tolerance. With outstanding chemical and UV resistance, they provide long-term performance and exceptional cost-effectiveness, making them a preferred solution for many containment and environmental protection projects.

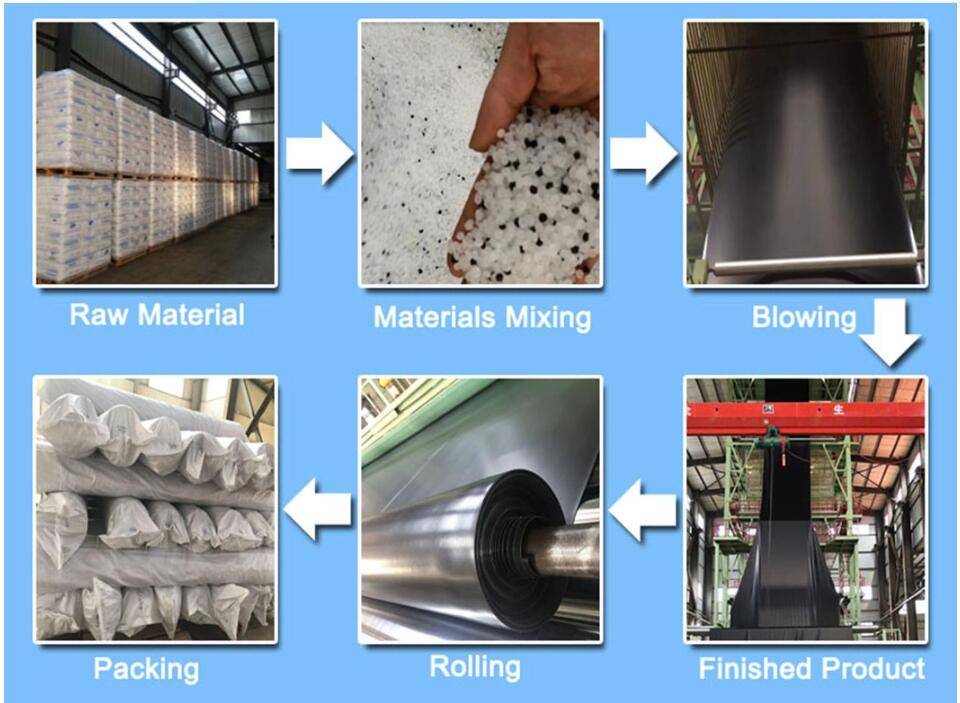

Flow of Production

Benefits of Geomembrane Sheets

HDPE geomembrane is the most chemically resistant material in the polyethylene family, thanks to its dense molecular structure. It is field-welded using hot wedge or extrusion welders, creating factory-quality seams that are virtually stronger than the liner itself. The product features industry-leading QC and QA testing standards, ensuring superior reliability and performance.

With excellent UV stability, the liner does not require additional cover, making it a highly cost-effective solution. It is supplied in roll form and available in various thicknesses from 20 to 120 mil, allowing customization to meet specific project requirements.

Applications

Landfill Lining

Prevents contamination of groundwater by creating an impermeable barrier between waste materials and the surrounding soil.

Landfill Capping

Stops fluid infiltration into the landfill, captures and safely vents gases produced by decomposing organic waste, and allows for effective revegetation and site restoration.

Water Reservoirs

Used to collect and store rainwater before it flows into the sea, supporting sustainable water management.

Wastewater Reservoirs

Provides reliable containment to prevent wastewater from polluting groundwater sources or nearby streams.

Pond Lining

Ideal for constructing artificial lakes and irrigation ponds, ensuring efficient water retention for agricultural or decorative use.

Irrigation Canals

A cost-effective alternative to concrete or compacted earth linings, used for water transport and irrigation over large areas. Also effective for minimizing seepage in older, deteriorated canal systems.

Packaging and Shipping

Technical Notes

HDPE is a highly technical material that requires professional handling during installation. It must be installed by certified welding technicians using specialized welding equipment to achieve optimal performance and long-term reliability. Installation conditions are sensitive to temperature and weather, so proper planning and timing are essential.

A 40 mil HDPE liner demands careful subgrade preparation to ensure a smooth and stable foundation. It is a great upgrade from lighter materials such as 20 mil RPE, making it suitable for larger projects or as a secondary containment layer in multi-layer systems (e.g., subgrade → geotextile → 40 mil HDPE → drainage net → 60 mil HDPE → geotextile → fill).

The 60 mil HDPE liner is the industry standard, offering an excellent balance of strength, flexibility, and cost-effectiveness for most containment and lining applications.

For more demanding conditions, the 80 mil HDPE liner provides enhanced durability and protection, making it ideal for installations over rough or aggressive subgrades.

FAQ

1. Where is our company located ?

Economic Development Zone, Ling County, Dezhou City, Shandong Province. China.

2. Can you send samples to us ?

Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

3. What's your Payment term ?

T/T , L/C , Western Union.

4. What's your delivery method ?

By sea , By train , By ari, depend on your country.