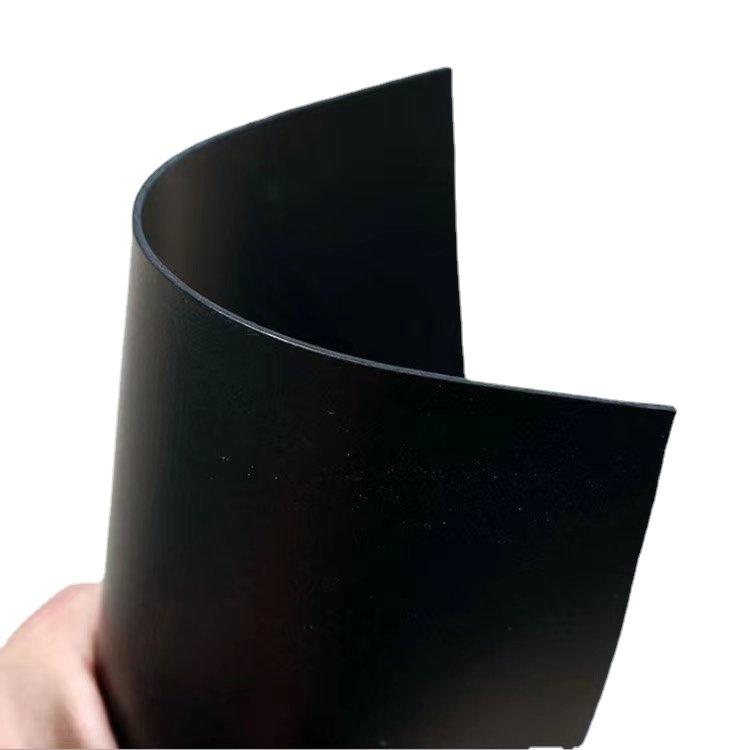

HDPE geomembrane liner

Excellent Anti-seepage Performance

Superior Chemical and UV Resistance

High Tensile Strength & Puncture Resistance

Long Service Life

Easy and Efficient Installation

HDPE geomembrane liner is the preferred product for lining projects. HDPE geomembrane liner is resistant to many different solvents and are the most widely used geomembrane liner in the world. Designed to exceed GRI-GM13 specification standards for HDPE geomembrane liners, it offers proven performance at the most competitive prices on the market.Its exceptional chemical and ultraviolet resistance properties make it an extremely cost-effective product.

Specification:

Test Property | Unit | Test Method | Minimum Average Value (per GRI GM13) | ||||||

Thickness (1) mm | ASTM D 5199 | 0.75 | 1.0 | 1.25 | 1.5 | 2.0 | 2.5 | 3.0 | |

Density | ASTM D 792 | ≥0.94

| |||||||

Strength at Yield (Both Directions) | ASTM D 6693 | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

Strength at Break (Both Directions) | Type IV Dumbbell, 50mm/min | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

Elongation at Yield (Both Directions) | % | Gage length 33 mm for Yield Elongation | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

Elongation at Break (Both Directions) | Gage length 50 mm for break Elongation | 700 | 700 | 700 | 700 | 700 | 700 | 700 | |

Tear Resistance | N | ASTM D 1004 | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

Puncture Resistance | N | ASTM D 4833 | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

Carbon Black Content | % | ASTM D 4218 | 2.0 - 3.0 | ||||||

Carbon Black Dispersion | Category | ASTM D 5596 | Note (2) | ||||||

Melt Flow Index (3) | g/10 min | ASTM D 1238 (190℃/2.16 kg) | ≤ 1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤ 1 |

Stress Crack Resistance (NCTL) | hr. | ASTM D 5397 | ≥500 | ≥500 | ≥500 | ≥500 | ≥500 | ≥500 | ≥500 |

Oxidative Induction Time (Standard; S-OIT) | min | ASTM D 3895 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

Oxidative Induction Time (High Pressure; HP-OIT) | min | ASTM D 5885 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

Oven Aging at 85℃ Standard OIT Retained after 90 days | % | ASTM D 3895 | 55 | 55 | 55 | 55 | 55 | 55 | 55 |

Oven Aging at 85℃ High pressure OIT Retained after 90 days | % | ASTM D 5885 | 80 | 80 | 80 | 80 | 80 | 80 | 80 |

UV resistance Standard OIT Retained after 1600hrs | % | ASTM D 3895 |

N.R.(4) | ||||||

UV resistance High pressure OIT Retained after 1600hrs | % | ASTM D 5885 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

Benefits of HDPE

The most chemically resistant member of the polyethylene family due to its dense configuration.

Field welded with hot wedge welders and extrusion welders. These factory quality welds are virtually stronger than the sheet itself.

The best QC-QA testing capabilities in the marketplace.

No need to cover the liner because it is UV stable = cost-effective.

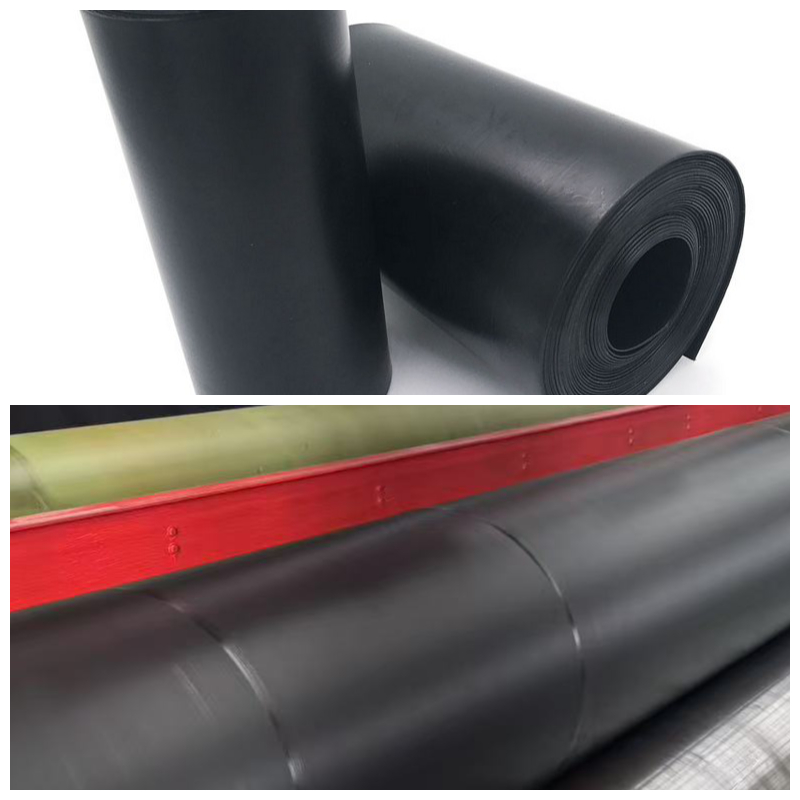

Available in roll stock and come in varying thicknesses ranging from 20 to 120 mil depending on your requirements.

Applications

Passive, self-activating secondary containment liner system best suited for containment around the transformer, rather than the perimeter of the substation

Perfect solution for transformers (live and spare), tank storage, wind farms and solar fields

For a smaller footprint, use corrugated HDPE pipe with the containment system to increase the void space

Use geomembrane liner to line chipped or cracked concrete containment