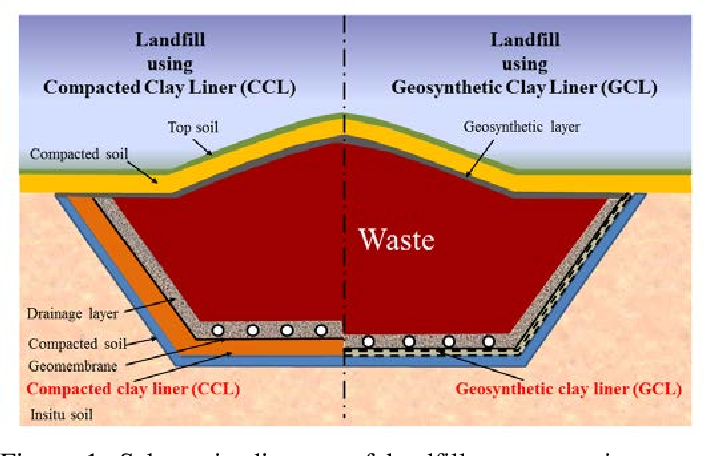

Geosynthetic Clay Liner For Landfill

Replaces thick compacted clay liners (1m CCL ≈ 10mm GCL)

Reduces construction time and overall cost

Provides consistent quality and uniform performance

Performs well under differential settlement

Compatible with geomembranes to form a composite liner system (GCL + HDPE)

GCL for Landfill — High-Performance Geosynthetic Clay Liner

Description:

GCL for landfill provides superior waterproofing for municipal and industrial landfills. Made with bentonite clay and geotextiles, it prevents leachate leakage and protects groundwater.

Product Overview

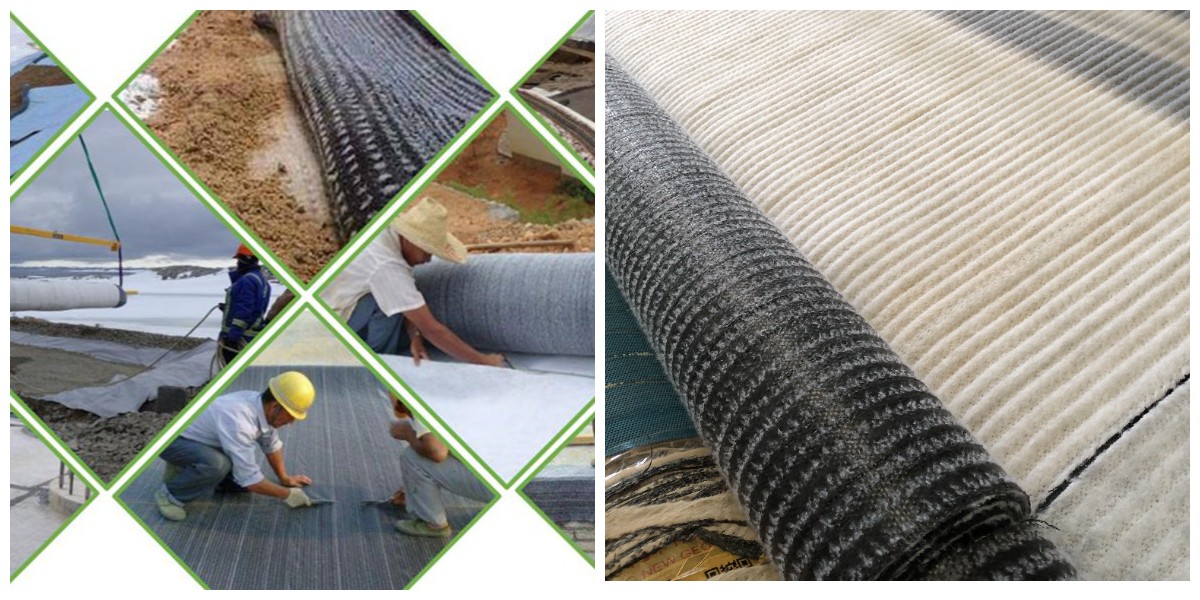

Geosynthetic Clay Liner (GCL) for landfill is a high-quality waterproofing solution designed to prevent leachate leakage and protect soil and groundwater. Composed of natural sodium bentonite clay sandwiched between woven and nonwoven geotextiles, the GCL swells upon hydration, forming a low-permeability barrier. It is widely used in landfill base liners, capping systems, and industrial waste containment projects.

Key Features

Superior Anti-Seepage: Bentonite clay forms a self-sealing hydraulic barrier with low permeability (≤ 5×10⁻¹¹ m/s).

Durable & Reinforced: Geotextile layers enhance tensile strength, puncture resistance, and long-term stability.

Self-Healing: Small punctures or tears automatically seal when hydrated.

Eco-Friendly: Natural clay material is safe for groundwater and environment.

Easy Installation: Lightweight and flexible, reducing labor and construction time.

Chemical Resistant: Stable performance under acidic or alkaline leachates.

Applications

Landfill Base Liners: Prevent leachate migration in municipal and hazardous waste landfills.

Landfill Capping Systems: Minimize rainwater infiltration and leachate generation.

Industrial Waste Containment: Chemical plants, mining tailings, and solid waste facilities.

Temporary Waste Storage & Transfer Stations: Environmental protection in waste handling sites.

Technical Specifications

| Property | Typical Value | Test Standard |

|---|---|---|

| Bentonite Mass per Unit Area | ≥ 4.5 kg/m² | ASTM D5993 |

| Hydraulic Conductivity | ≤ 5×10⁻¹¹ m/s | ASTM D5084 |

| Tensile Strength | ≥ 600 N/100mm | ASTM D4595 |

| Peel Strength | ≥ 450 N/m | ASTM D6496 |

| Swell Index | ≥ 24 mL/2g | ASTM D5890 |

Advantages

Reduces need for thick compacted clay liners (CCL).

Saves time and construction costs.

Provides uniform, consistent performance.

Works well under differential settlement.

Can be combined with HDPE geomembranes for composite liner systems.

Packaging & Delivery

Roll Width: 1–6 meters

Roll Length: 20–40 meters (customizable)

Packaging: PE film wrapping or palletized for export

Delivery Time: 15–20 days after order confirmation