Smooth Geomembrane

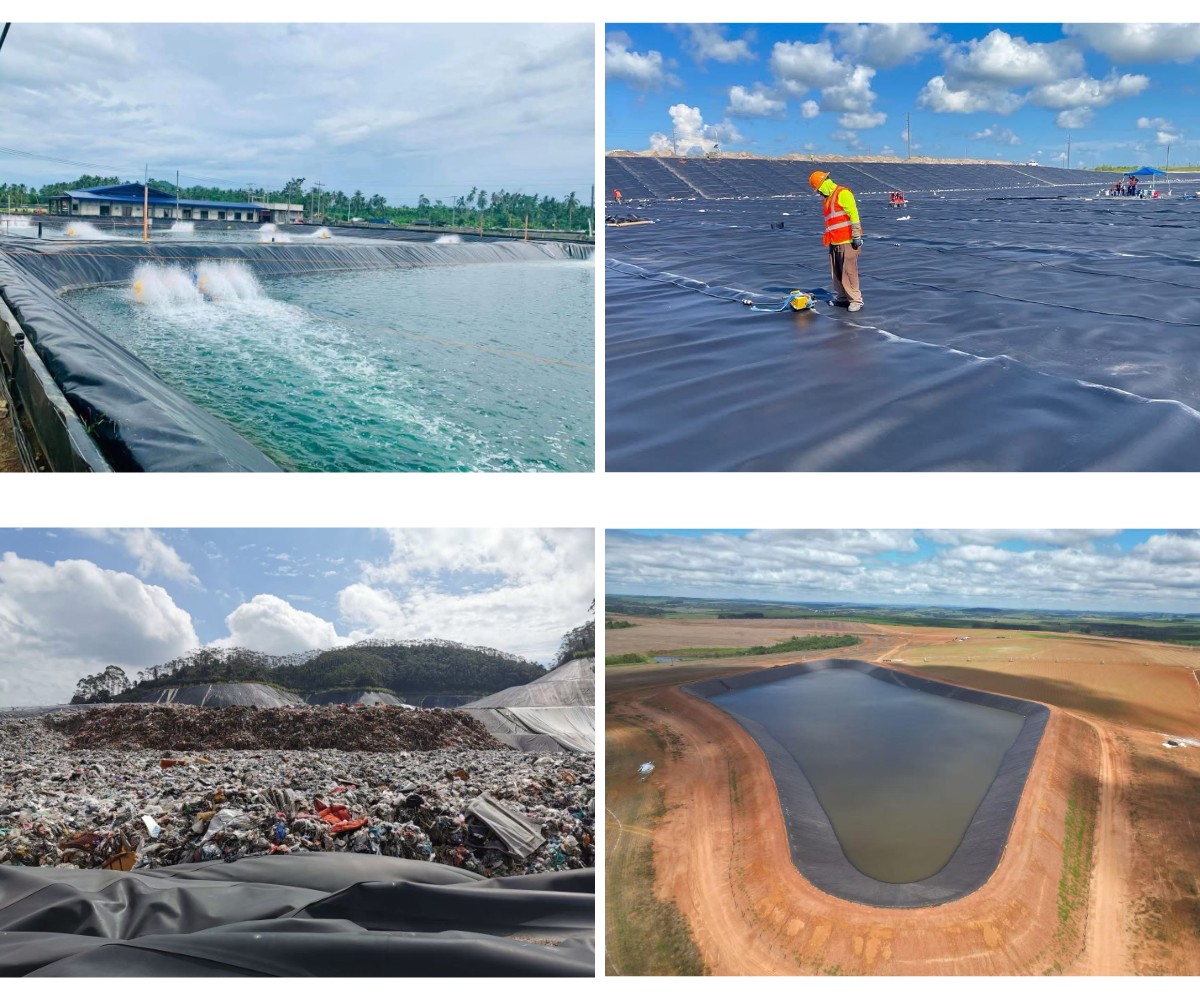

Smooth Geomembranes are engineered synthetic sheets made from high-density polyethylene resins. They are widely utilized as liners or barriers in construction and environmental protection projects because of their exceptional chemical resistance, long-lasting durability, flexibility, and impermeability. Common applications include lining landfills, ponds, and other containment systems.

Excellent Chemical Resistance – Resists a broad spectrum of acids, alkalis, and chemicals.

High Durability – Offers strong resistance to aging and weathering for an extended service life.

Superior Flexibility – Easily conforms to uneven surfaces and structures, facilitating installation.

Outstanding Impermeability – Ensures dependable seepage control and protects the environment.

Versatile Applications – Suitable for landfills, ponds, reservoirs, and diverse containment projects.

Smooth Geomembranes are manufactured from high-quality HDPE resins. They are commonly used as liners or barriers in construction and environmental protection projects due to their outstanding chemical resistance, durability, flexibility, and impermeability. Typical uses include lining landfills, sealing ponds, and other containment applications.

Flow of Production

Benefits of HDPE Liners

Using HDPE (High-Density Polyethylene) liners offers several benefits across different applications due to their unique properties and performance characteristics:

UV resistance:HDPE geomembranes incorporate 2–3% carbon black , which acts as a UV absorber. This additive effectively blocks ultraviolet radiation, minimizing polymer chain degradation and extending service life in exposed applications (e.g., landfill caps, pond liners).

Impermeability: HDPE liners provide excellent impermeability to liquids, gases, and solids. They create a reliable barrier that prevents the passage of contaminants, leachate, and hazardous materials into the surrounding environment. This property is crucial in applications such as landfills, wastewater treatment facilities, and industrial containment areas.

Chemical Resistance: HDPE liners exhibit high resistance to a wide range of chemicals, including acids, alkalis, and organic solvents. This makes them suitable for use in environments where exposure to corrosive substances is common, ensuring long-term durability and performance.

Durability and Longevity: HDPE liners are known for their durability and resistance to punctures, tears, and UV radiation. They have a long service life and can withstand harsh environmental conditions without degradation, reducing the need for frequent maintenance or replacement.

Flexibility and Ease of Installation: HDPE liners are flexible and can conform to irregular surfaces and terrain. This flexibility simplifies installation processes, reduces labor costs, and allows for efficient coverage of large areas. HDPE liners can be prefabricated into large panels or rolls, facilitating rapid deployment and minimizing onsite seaming.

Cost-Effectiveness: HDPE liners offer cost-effective solutions for containment and environmental protection compared to alternative materials. Their durability, minimal maintenance requirements, and long service life contribute to lower life cycle costs over the lifespan of a project.

Parameters

S/N | Item | Index | ||||||

Thickness mm | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 | |

1 | Density g/cm3 | ≥0.940 | ||||||

2 | Tensile yield strength (vertical and horizontal) N/mm | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 |

3 | Tensile breaking strength (vertical and horizontal) N/mm | ≥20 | ≥27 | ≥33 | ≥40 | ≥53 | ≥67 | ≥80 |

4 | Elongation (vertical and horizontal) % | - | - | - | ≥12 | |||

5 | Elongation at break (vertical and horizontal) % | ≥700 | ||||||

6 | Tearing load at right angle (vertical and horizontal) N | ≥93 | ≥125 | ≥160 | ≥190 | ≥250 | ≥315 | ≥375 |

7 | Anti-puncture strength N | ≥240 | ≥320 | ≥400 | ≥480 | ≥540 | ≥800 | ≥960 |

8 ' | Tensile load stress cracking (tensile method of dead load of the cut) h | _ | ≥300 | |||||

9 | Carbon black content % | 2.0~3.0 | ||||||

10 | Carbon black dispersion | The number of Level 3 among 10 data is not more than one; Level 4 and Level 5 are not allowed. | ||||||

Oxidation induction time (OIT) min | Oxidation induction time under normal pressure ≥100 | |||||||

11* | Oxidation induction time under disjoining pressure ≥400 | |||||||

12 | 85°C thermal aging (retention rate of OIT under normal pressure after 90d) % | ≥55 | ||||||

13a | Ultraviolet resistance (retention rate of OIT after 1600h ultraviolet irradiation) | ≥50 | ||||||

Note: Technical performance index of thickness specification not listed in the table shall be implemented according to interpolation method. | ||||||||

For two indexes of Item 11 and Item 13, select one from retention rate of OIT under normal pressure and retention rate of OIT under high pressure and carry out the test. | ||||||||

Applications

Landfills: Geomembranes are widely used as liners in landfills.

Mining heap leach & slag tailing ponds

Pond Liners: Geomembranes are used in the construction of ponds, reservoirs, and lagoons for water storage, wastewater treatment, and aquaculture.

Secondary Containment: Geomembranes are employed in secondary containment systems around storage tanks, pipelines, and industrial.

Wastewater Treatment: Geomembranes are used in the construction water treatment plants.Irrigation ponds, canals, ditches & water reservoirs

Our geomembranes are also used for floating covers and bio-gas containment.

Packaging&Shipping