pvc geomembrane liner

• Superior Impermeability

• Excellent Flexibility & Toughness

• Strong Chemical & Environmental Resistance:

• Easy Installation & Sealing

• Cost-Efficient & Long-Lasting

1. Introduction

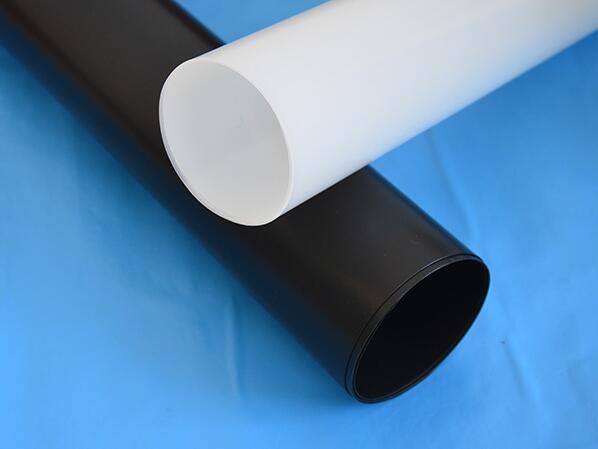

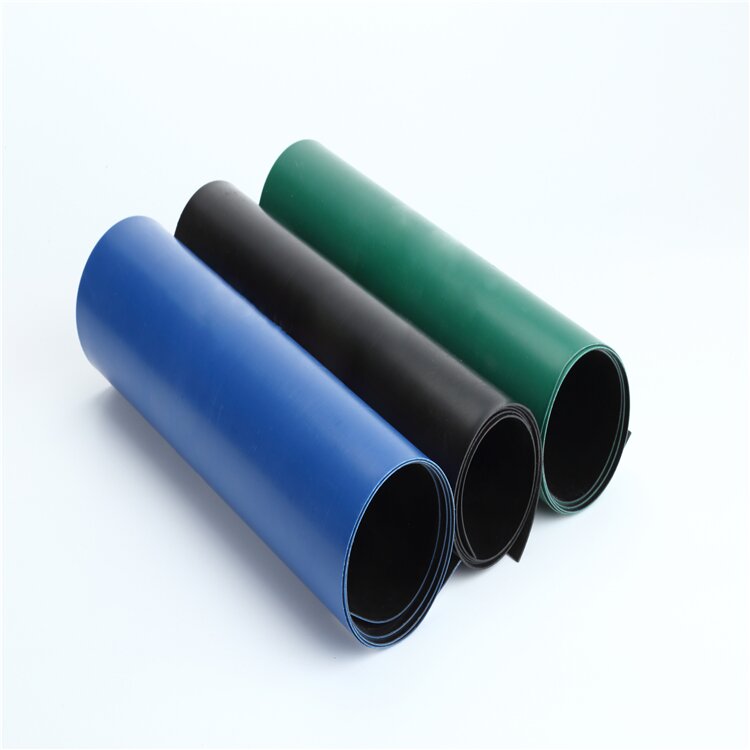

PVC (Polyvinyl Chloride) geomembrane is a premium synthetic waterproofing and anti-seepage geosynthetic material produced by calendering, extrusion, or blow molding of PVC resin blended with plasticizers, stabilizers, and anti-aging additives.

It features a dense, homogeneous structure with outstanding impermeability, flexibility, and chemical resistance, acting as a core barrier material in engineering projects requiring strict leakage control and environmental protection.

2. Core Advantages

• Superior Impermeability: Near-zero water vapor transmission rate effectively blocks the migration of water, chemicals, and contaminants, ensuring reliable anti-seepage performance.

• Excellent Flexibility & Toughness: Maintains ductility even at low temperatures (-20°C to -30°C), adapting to substrate deformation without cracking or peeling.

• Strong Chemical & Environmental Resistance: Resists corrosion from acids, alkalis, salts, and organic solvents; UV-stabilized formulas prevent aging, fading, and brittleness under long-term outdoor exposure.

• Easy Installation & Sealing: Lightweight design facilitates on-site handling; hot-air welding or solvent bonding creates seamless joints with strength comparable to the membrane itself.

• Cost-Efficient & Long-Lasting: Competitive production costs combined with a service life of 15–20 years (under proper use) reduce long-term maintenance and replacement expenses.

3. Key Applications

• Water Conservancy & Hydraulic Engineering: Reservoir, pond, and canal liners for water conservation; anti-seepage of artificial lakes, golf course water features, and irrigation systems.

• Environmental Protection & Waste Management: Landfill liners (municipal solid waste, hazardous waste) and leachate collection systems; sewage treatment pond anti-seepage and chemical storage tank secondary containment.

• Infrastructure & Construction: Subway and tunnel waterproofing; basement and foundation anti-seepage; roof garden and landscape pond liners.

• Agriculture & Aquaculture: Greenhouse soil moisture retention films; fish pond, shrimp pond, and aquaculture tank liners to prevent water loss and soil erosion.

4. Production Process Flow

1. Raw Material Formulation: Mix PVC resin (primary material) with plasticizers, heat stabilizers, UV absorbers, anti-oxidants, and other additives in precise proportions to ensure product performance.

2. Mixing & Kneading: Feed the formulated materials into a high-speed mixer for homogenization, then transfer to an internal mixer or open mill for heating (140–160°C) and kneading to form a uniform PVC compound.

3. Calendering/Extrusion: For sheet-type geomembranes, use a multi-roll calender to press the compound into continuous films of specified thickness (0.3–3.0mm); for thick or large-width products, adopt extrusion molding via a T-die extruder.

4. Cooling & Shaping: Pass the extruded/calendered film through a cooling roller set to solidify and stabilize its dimensions, ensuring flatness and uniform thickness.

5. Post-Treatment: Conduct surface treatment (e.g., embossing for enhanced friction) or edge trimming based on application needs; perform quality tests (impermeability, tensile strength, weldability).

6. Winding & Packaging: Wind the qualified geomembrane into coils of standard width (2–8m) and length (50–100m), label with technical parameters, and package for storage and transportation.