Excellent Impermeability – Provides reliable seepage control for aquaculture and water containment.

UV & Aging Resistance – Performs well in exposed outdoor conditions with long service life.

High Durability – Made from premium virgin HDPE resin with superior mechanical strength.

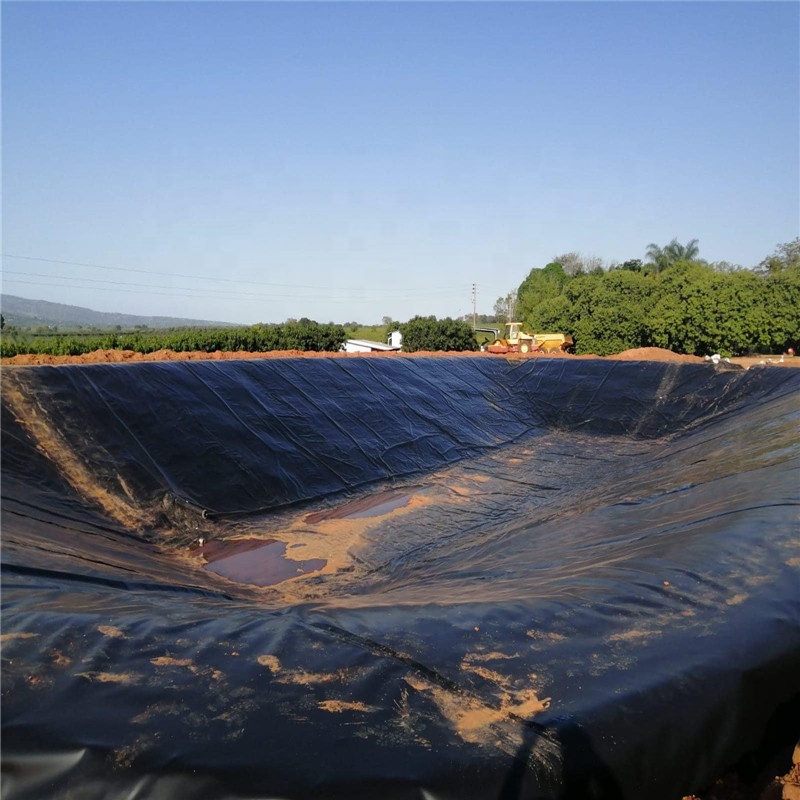

Ideal for Aquaculture – Perfect liner solution for shrimp ponds, fish farms, and water reservoirs.

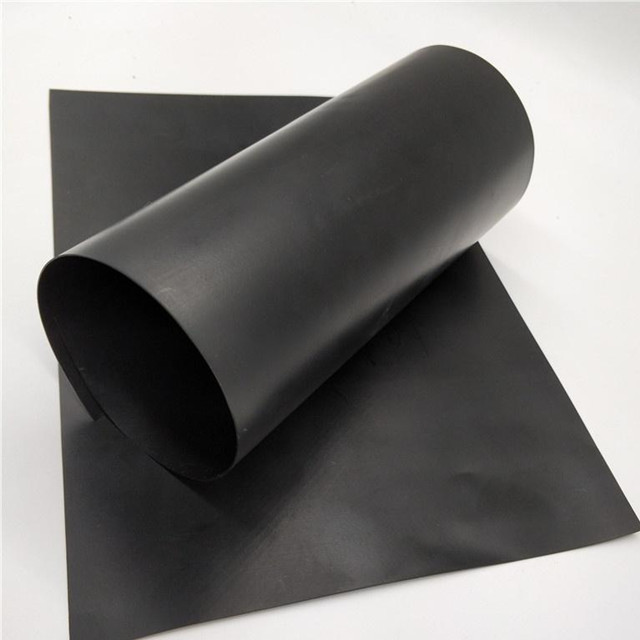

Geomembrane in HDPE

HDPE geomembrane is a low-permeability synthetic liner and geotechnical material widely used in aquaculture and water containment projects. It is manufactured from premium quality high-density polyethylene (HDPE) using specially formulated virgin resin blended with carbon black, antioxidants, anti-aging agents, and UV-resistant components. These additives provide excellent UV resistance and long-term durability, making the smooth HDPE geomembrane ideal for exposed environments. It is the perfect impermeable material for shrimp farming and aquaculture ponds

Product Details

Geomembrane in HDPE is the low permeable synthetic geomembrane liner and geotechnical engineering materials which are widely used for acquanculture and water containment applications. HDPE Geomembrane is made of finest quality high density polyethylene (HDPE) with specially formulated, virgin polyethylene resin, combined with specified quantity carbon black, antioxidant, anti-aging agent and UV resistance components, which makes our smooth geomembrane HDPE Geomembrane with excellent resistance to UV radiation and is suitable for exposed conditions. HDPE Geomembrane is the ideal low permeable synthetic material for Shrimp farming.

Flow of Production

Specification

Item | Test Value | ||||||

0.3mm | 0.5mm | 0.75mm | 1.0 mm | 1.5 mm | 2.0mm | 3.0mm | |

Minimum Density(g/cm³) | 0.94 | ||||||

Strength at yield,N/mm | 5 | 8 | 11 | 15 | 22 | 29 | 44 |

Strength at break ,N/mm | 8 | 14 | 20 | 28 | 40 | 53 | 80 |

Elongation at yield,% | 13 | ||||||

Elongation at break,% | 720min | ||||||

Tear Resistance N | 40 | 65 | 93 | 125 | 190 | 250 | 375 |

Puncture Resistance N | 105 | 176 | 240 | 320 | 480 | 640 | 960 |

Stress Crack Resistance, hrs | 300 | ||||||

Carbon Black Content, % | 2.0-3.0 | ||||||

Carbon Black Dispersion | 1 or 2 | ||||||

Standard OIT Min | 100 | ||||||

High Pressure OIT Min | 400 | ||||||

85℃ Heat aging(OIT Retention rate at Normal pressure after 90d ) % | 85 | ||||||

UV resistance (OIT retention rate after 1600 hours of UV radiation) | 65 | ||||||

Impact Cold Crack at -70°C | Pass | ||||||

Water vapor permeability (g.cm/cm2 .s.Pa) | ≤1.0×10-13 | ||||||

Dimensional Stability (%) | ±2 | ||||||

Application

1. Prevent leakage disposal in waste burying field or waste water or waste dregs disposing field,river bank,lake dam ,mine

remainings ,reservior,tunnel,liquid storage

2. Preventing leakage in subway ,basement,tunnel ,hole

3. Anti-solt leakage in roadbed and other groundtill

4. The plane direction laying of dam ,the vertical direction laying fou groundtill ,used in the construction fence and waste

material field

5. Used in seawater or freshwater feed field, groundtill of road,highway ,railway and waterproof layer of swelling clay and wet

collapsed loess

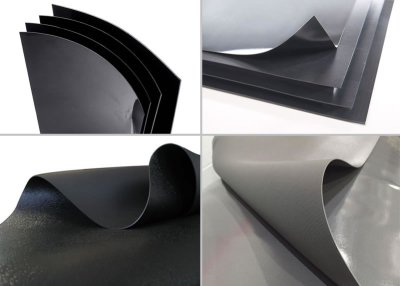

Features

1. Good physical and mechanic performance

2. High tearing resistance, strong deformation adaptability

3. Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance

4. Good adaptability to high and low temperature, non-toxicity, long service life

5. Good waterproof, drainage, anti-seepage and damp proof effects

6. Complete width and thickness specifications, low cost and easy installation.

Packing and Delivery

1. The products are usually tied with packing tape.The packaging size and container capacity of the product are different from the product specifications

2. Container transportation, according to your project request. Production time usually costs 10-20 days.

3. Port: Qingdao

Leave your messages