good pvc geomembrane

• Industry-Leading Impermeability

• All-Climate Flexibility

• Proven Durability & Chemical Resistance

• Cost-Effective Installation

• Eco-Conscious Design

1. Introduction

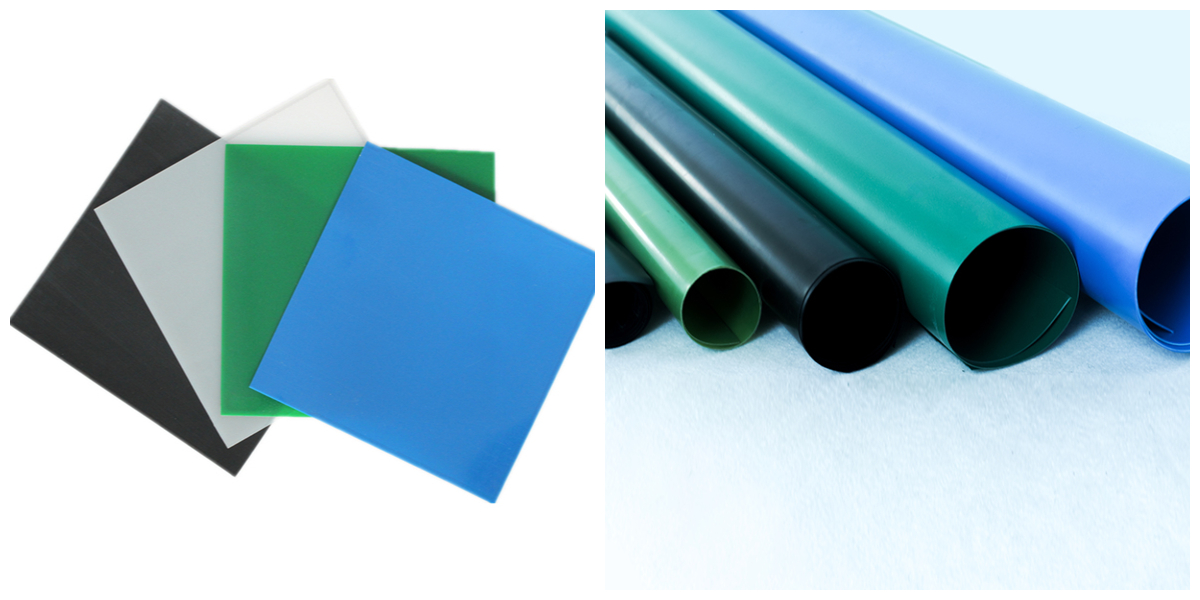

PVC (Polyvinyl Chloride) geomembrane stands as a cornerstone geosynthetic barrier in global infrastructure and environmental projects, engineered from PVC resin with advanced plasticizers, UV stabilizers, and reinforcing additives.

Renowned for its impermeable, flexible, and durable properties, it has become the material of choice for engineers, contractors, and environmental regulators worldwide—delivering reliable leakage control and long-term stability across

diverse climates and project scales. Unlike traditional waterproofing materials, its homogeneous structure and adaptability make it a versatile solution for both large-scale civil works and precision environmental protection initiatives.

2. Core Advantages (Global Industry Recognition)

• Industry-Leading Impermeability: Boasts near-impermeable performance (water vapor transmission rate < 1×10⁻¹¹ g/(cm·s·Pa)), meeting strict international standards (e.g., ISO 10818, ASTM D4439) for containing water, chemicals, and

hazardous substances—critical for environmental compliance.

• All-Climate Flexibility: Maintains ductility even in extreme temperatures (-30°C to 70°C), performing reliably in frigid northern construction sites (e.g., Canadian pipeline projects) and hot, arid regions (e.g., Middle Eastern water reservoirs)

without cracking or brittleness.

• Proven Durability & Chemical Resistance: Resists corrosion from acids, alkalis, salts, and organic solvents, with a service life of 15–25 years under proper installation—aligning with global sustainable infrastructure goals (e.g., EU Green Deal,

US Infrastructure Investment and Jobs Act).

• Cost-Effective Installation: Lightweight (typically 0.5–3.0 kg/m²) and compatible with hot-air welding or solvent bonding, enabling fast, seamless deployment that reduces labor costs and project timelines—ideal for large-scale projects like landfill cells or reservoir liners.

• Eco-Conscious Design: Low-VOC (volatile organic compound) formulations meet global environmental regulations; recyclable at end-of-life, supporting circular economy initiatives adopted by governments and private sector clients worldwide.

3. Global Key Applications

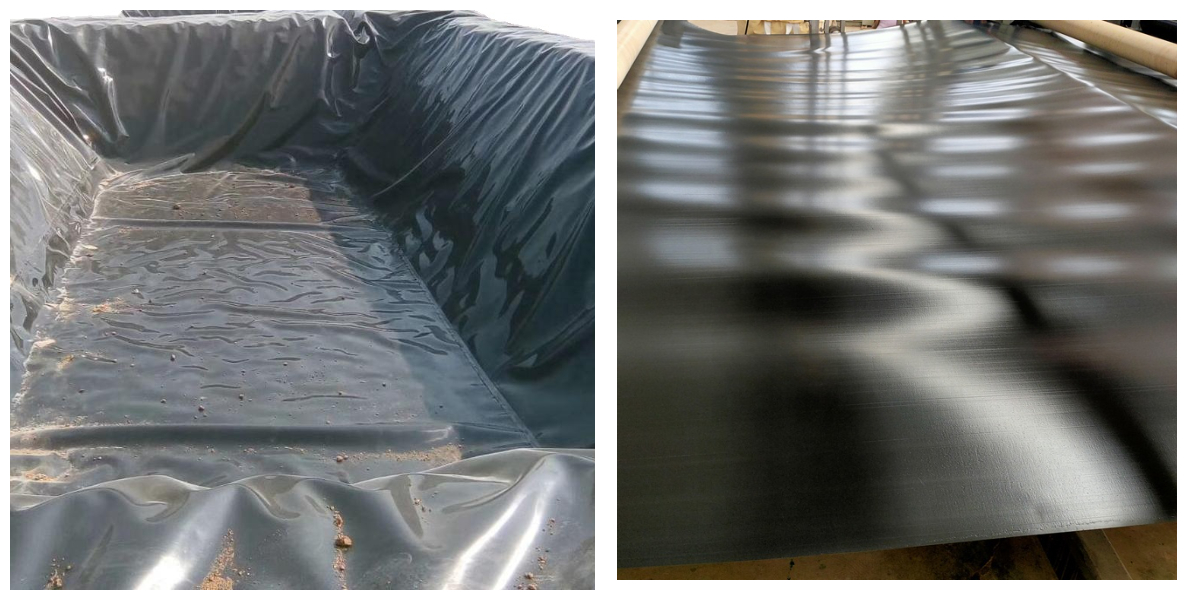

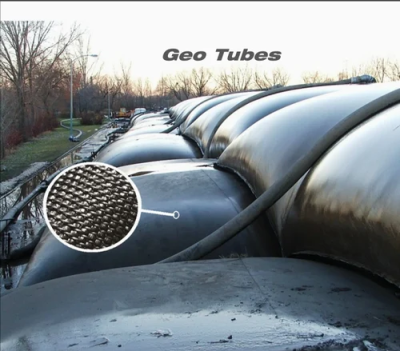

• Environmental Protection (Global Compliance): Landfill liners and leachate collection systems (complying with EPA, EU Landfill Directive standards) to prevent soil and groundwater contamination; sewage treatment plant covers and chemical storage seco

containment.

• Water Resources Management: Reservoir, canal, and aqueduct liners for water conservation (critical in water-scarce regions like Australia and the American Southwest); artificial lakes, golf course water features, and coastal erosion control projects

(e.g., European coastal defense systems).

• Civil Infrastructure: Subway and tunnel waterproofing (e.g., Tokyo Metro, London Crossrail); basement and foundation barriers for commercial buildings; roadbed and railway embankment waterproofing to protect structural integrity.

• Agriculture & Aquaculture: Greenhouse soil moisture retention films (popular in Europe and Southeast Asia); high-density fish pond and shrimp farm liners (used extensively in Norway, Chile, and Southeast Asian aquaculture hubs) to maximize yield and water efficiency.

4. International Production Process Flow

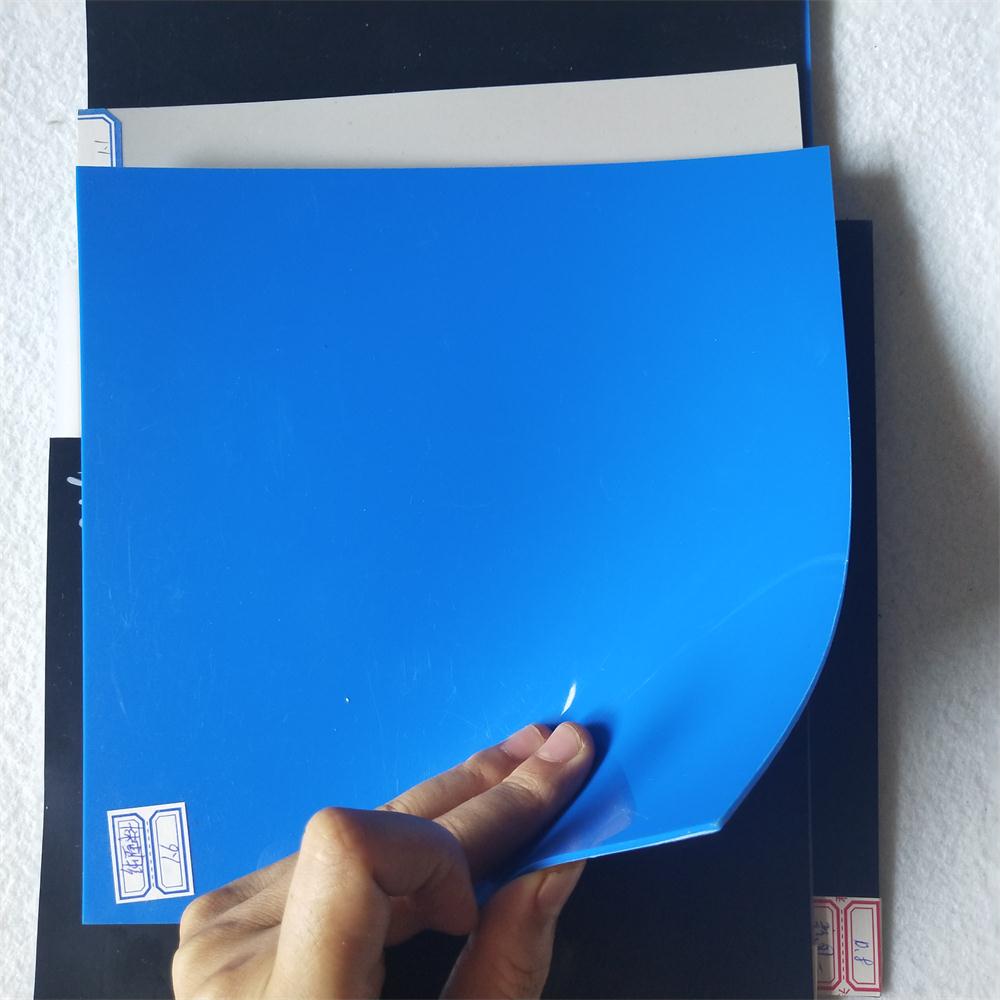

1. Raw Material Sourcing & Formulation: High-purity PVC resin (sourced from global suppliers like Dow, Formosa) is blended with food-grade plasticizers, UV absorbers, and heat stabilizers—meeting international safety standards (e.g., REACH, FDA) for contact with

potable water or food-related applications.

2. Compound Mixing: The formulation is homogenized in high-speed mixers, then melted and kneaded in internal mixers at 140–160°C to form a consistent PVC compound—ensuring uniform performance across the final product.

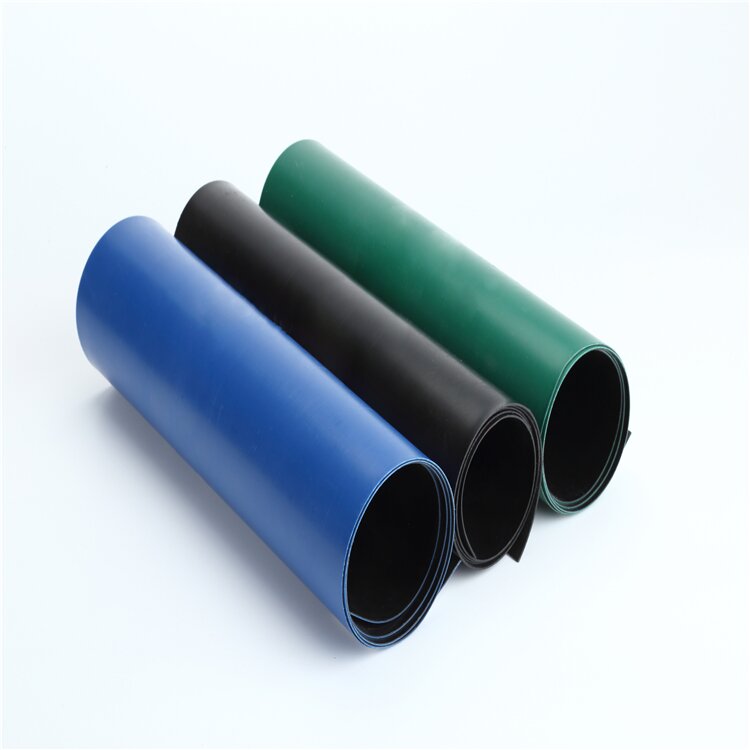

3. Extrusion/Calendering: For large-width products (up to 8m), T-die extrusion is used to form continuous sheets; calendering (via multi-roll machines) is employed for precise thickness control (0.3–3.0mm)—common in European and North American manufacturing

facilities.

4. Cooling & Surface Treatment: The extruded film is cooled via water-cooled rollers to stabilize dimensions; optional embossing (for enhanced friction) or corona treatment (to improve weldability) is applied based on client requirements (e.g., anti-slip surfaces for

walkways).

5. Quality Control (Global Standards): Rigorous testing is conducted per ISO 10818, ASTM D4439, and EN 13361—including impermeability tests, tensile strength checks, weldability verification, and UV aging resistance assessments—ensuring compliance with

client-specific regional standards.

6. Winding & Logistics: Qualified geomembrane is wound into coils (standard lengths: 50–100m) with protective packaging; labeled with technical data, batch numbers, and compliance certifications for global shipping to projects worldwide.