Long Fiber Nonwoven Geotextile

1.Filtration

2.Separation

3.Drainage

4.Liner protection

5.Reinforcement

PET Long Fiber Nonwoven Geotextile

Product Description

PET (Polyester) Long Fiber Nonwoven Geotextile is 100% Polyester Continuous Filament Needle Punched non-woven Geotextile, with maximum 6m-width. These synthetic fibers are made into flexible, porous fabrics by standard weaving machinery or are knitted in a random nonwoven manner. The major point is that PET(Polyester) Long Fiber Nonwoven geotextiles are porous to liquid flow across their manufactured plane and also within their thickness, but to a widely varying degree. PET Long Fiber Nonwoven Geotextile have a very high melting point and UV resistance, and have many applications in filtration and separation, protection and drainage.

The package of nonwoven geotextile is PE, the colour of package is black, the MOQ (minimium order quantity)of white of is 20'GP, the one of grey is 40'HQ, the PET(Polyester) Long Fiber Nonwoven Geotextile could be made into bag, pot, roll or according to customers' requirements.

Mechanical Properties of PET Long Fiber Nonwoven Geotextile

(Hongxiang Geosynthetics can produce Hongxiang according to your requirement in constructions, minimium order quantity: 20'ft Container)

Nonwoven Geotextiles have main functional mechanical properties, permeable or impermeable properties, soil-tightness. The data sheet as blow is part of mechanical properties, not full of it. The permeabile properties, loading quantities or anyother details will be mailed to you if you need.

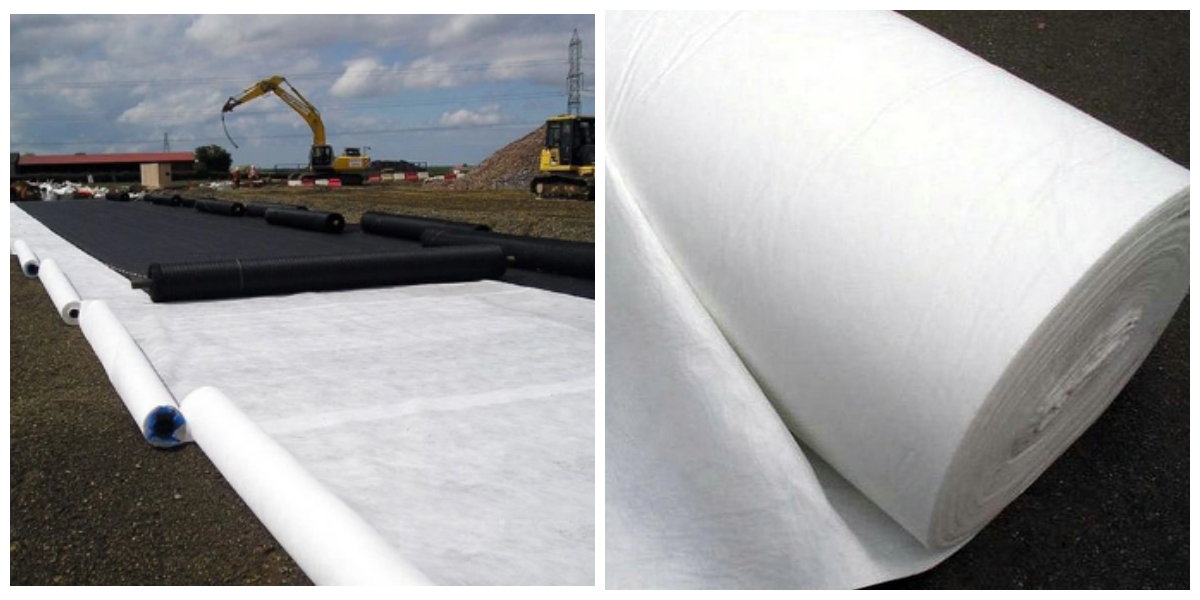

Filtration

The continuous filament structure of nonwoven geotextiles permits water to pass through while preventing soil migration. Spunbonded polyester nonwoven geotextiles are more cost effective than natural filters when used for revetment and subsoil drainage applications.

Separation

Nonwoven continuous filament geo fabrics are suitable for separating two layers of soil with different physical properties. Separating soft ground from coarse fill material reduces the amount of fill required and increases the life span of civil engineering structures such as roads and railways. They are frequently used in railway construction to separate the capping layer from the ballast layer.

Drainage

Nonwoven geotech fabrics improve the drainage performance of subsoil drainage systems in roads, railways, sports fields and behind retaining walls. They are ideal for draining or venting soils, such as the gas vent layer in a landfill cap.

Liner protection

Needle free nonwoven geotextiles are ideal for protecting HDPE liners from punctures and excessive deformation. The cushioning relieves stress and minimises the chance of contained harmful liquids or landfill waste leaking.

Reinforcement

The strength offered by nonwoven continuous fibre geotextiles can improve the load bearing capacity of a soil’s structure, such as the reinforcement of a retaining wall.