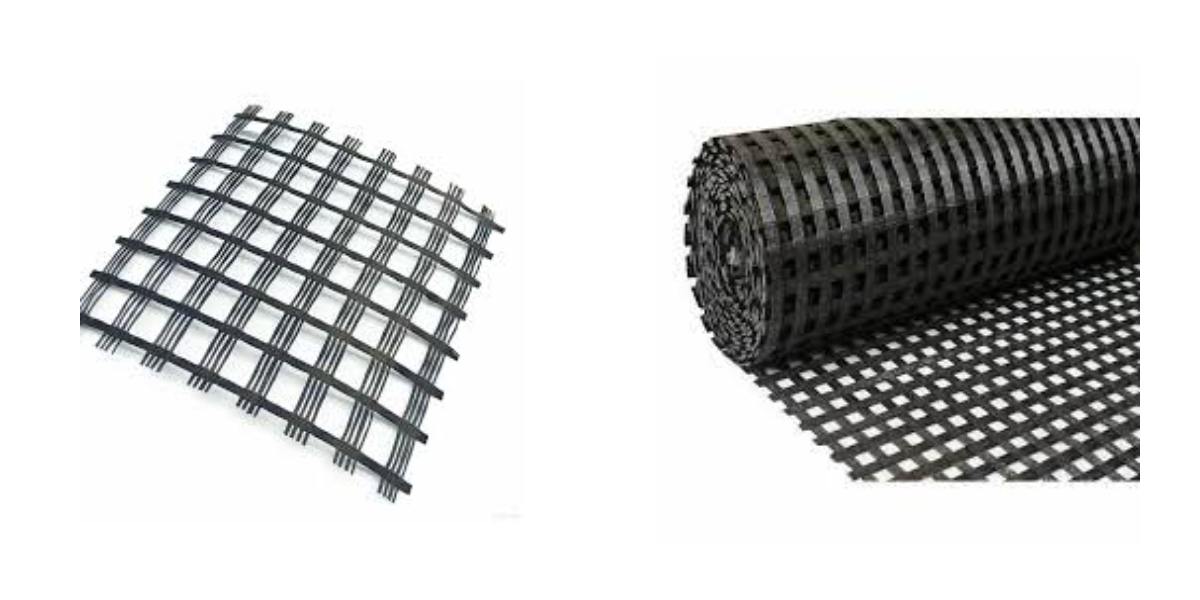

Asphalt Pavement Fiberglass Geogrid

Good wear and creep resistance.

Good fatigue cracking resistance.

High tensile strength.

Small deformation.

Excellent thermal stability.

Best Solution to Asphalt Pavement - Fiberglass Geogrid

Introduction:

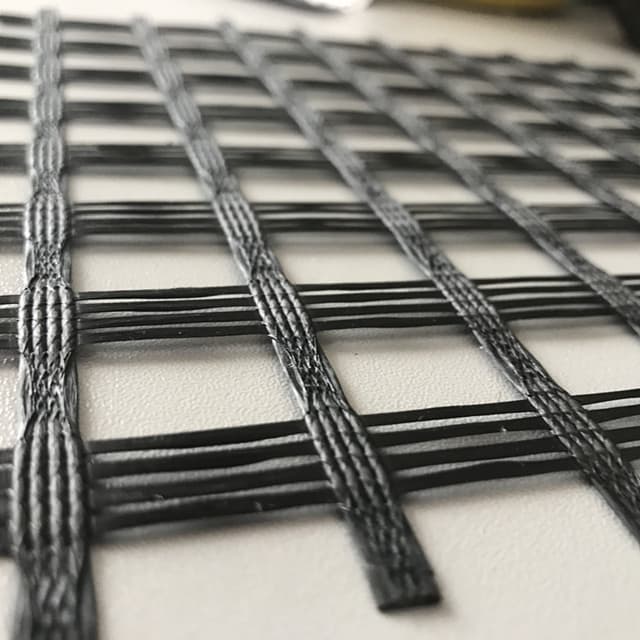

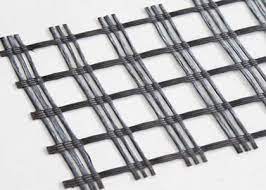

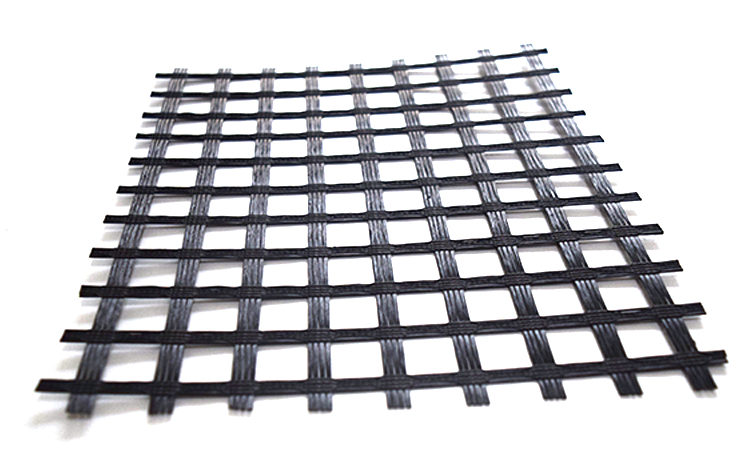

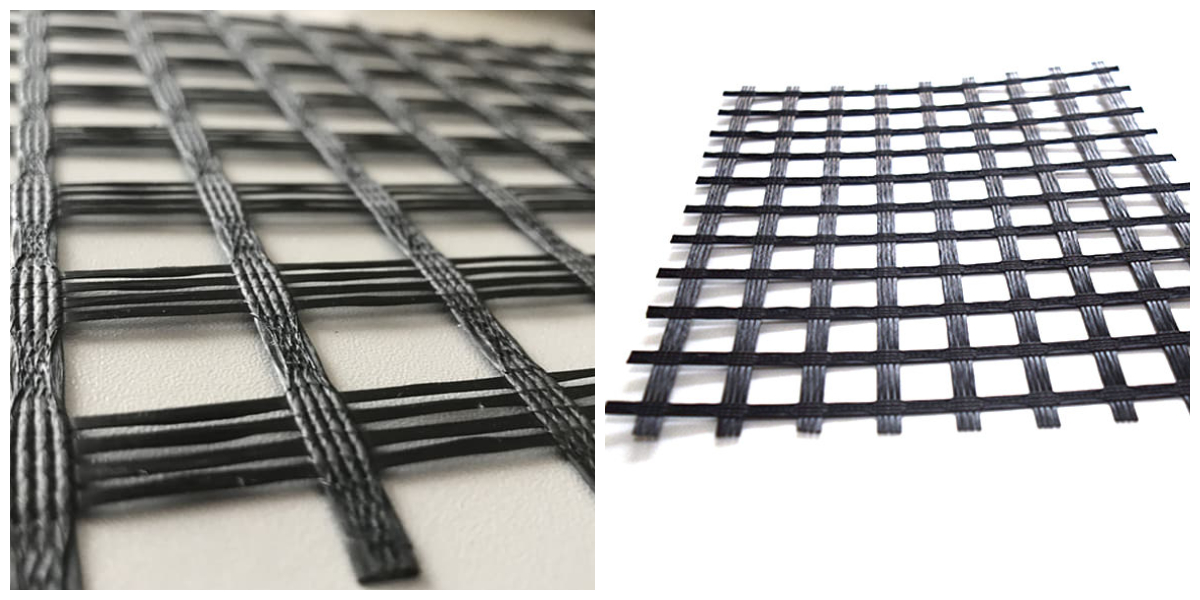

Fiberglass geogrid is a new type of geosynthetic material. It is made from fiberglass filament. This product adopts unique woven technique. It is coated with a special solution. Fiberglass geogrid has strong tension. It can largely increase the bearing capacity of the ground and prolongs the service life of the road. This material has high tensile strength and good wear resistant performance. It is suitable for the reinforcement of soft soil, cement, concrete, asphalt and so on. Compared with steel plastic geogrid, fiberglass geogrid has better heat resistance. This material is characterized by excellent thermal stability. It performs well under high temperature.

Fiberglass geogrid has long term structural stability. It is suitable for permanent projects. Fiberglass geogrid is extensively used in asphalt pavement, soil stabilization and embankment reinforcement. It can effectively prevent the ground from cracking and subsiding. Applying this product can reduce the overlay thickness of asphalt, thereby, fiberglass geogrid can greatly reduce the construction cost and project investment.

Features:

The product has the characteristics of high strength, low elongation, high temperature resistance, high modulus, light weight, good toughness, corrosion resistance, long life and so on. In engineering fields such as slope protection, road and bridge pavement enhancement treatment, it can strengthen and reinforce the pavement, prevent pavement rutting fatigue cracks, hot-cold expansion cracks and reflection cracks below, and can disperse the bearing stress of the pavement, prolong the service life of the pavement, high Low tensile strength, low elongation, no long-term creep, good physical and chemical stability, good thermal stability, anti-fatigue cracking, high temperature rutting resistance, low temperature shrinkage crack resistance, delay and reduce reflection cracks.

Application:

1. The old asphalt concrete pavement is reinforced to strengthen the asphalt surface layer to prevent diseases.

2. The cement concrete pavement is converted into a composite pavement to suppress reflection cracks caused by plate shrinkage.

3. Road extension and improvement project to prevent cracks caused by the junction of new and old and uneven settlement.

4. Reinforcement treatment of soft soil foundation is conducive to the consolidation of soft soil water separation, effectively inhibits settlement, uniform stress distribution, and enhances the overall strength of the roadbed.

5. The semi-rigid base of the newly built road produces shrinkage cracks, and the reinforcement is reinforced to prevent the pavement cracks caused by the reflection of the base cracks.

Specification:

Property | Test method | TGSB 30-30 | TGSB 40-40 | TGSB 50-50 | TGSB 60-60 | TGSB 70-70 | TGSB 80-80 | TGSB 90-90 | TGSB 100-100 | TGSB 120-120 | TGSB 130-130 | ||

Ultimate tensile strength | KN/m | MD | EN ISO 10139 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 120 | 130 |

CD | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 120 | 130 | |||

Elongation at maximum load | % | MD | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

CD | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |||

Approximate mesh size | mm | 12-50 | |||||||||||

Roll width | m | 1-6 | |||||||||||

Roll length | m | 50-200 | |||||||||||