lldpe geomembrane price

Excellent Impermeability

High Flexibility & Toughness

Durability: UV-resistant, chemical-resistant

Easy Installation

Cost-Effective: Long service life (15-20 years)

1. Production Process of LLDPE Geomembrane

1. Raw Material Preparation: High-grade linear low-density polyethylene (LLDPE) resin is selected, blended with UV stabilizers, anti-oxidants, and anti-aging additives to enhance durability in harsh environments.

2. Extrusion: The mixed resin is melted in an extruder at 160-190℃, then uniformly extruded through a flat die to form a continuous molten film.

3. Calendering & Thickness Control: The molten film passes through a series of calender rolls to adjust thickness (0.5-3.0mm, customizable) and ensure uniform flatness.

4. Cooling & Solidification: The film is cooled rapidly via air cooling or water cooling systems to maintain structural stability and prevent deformation.

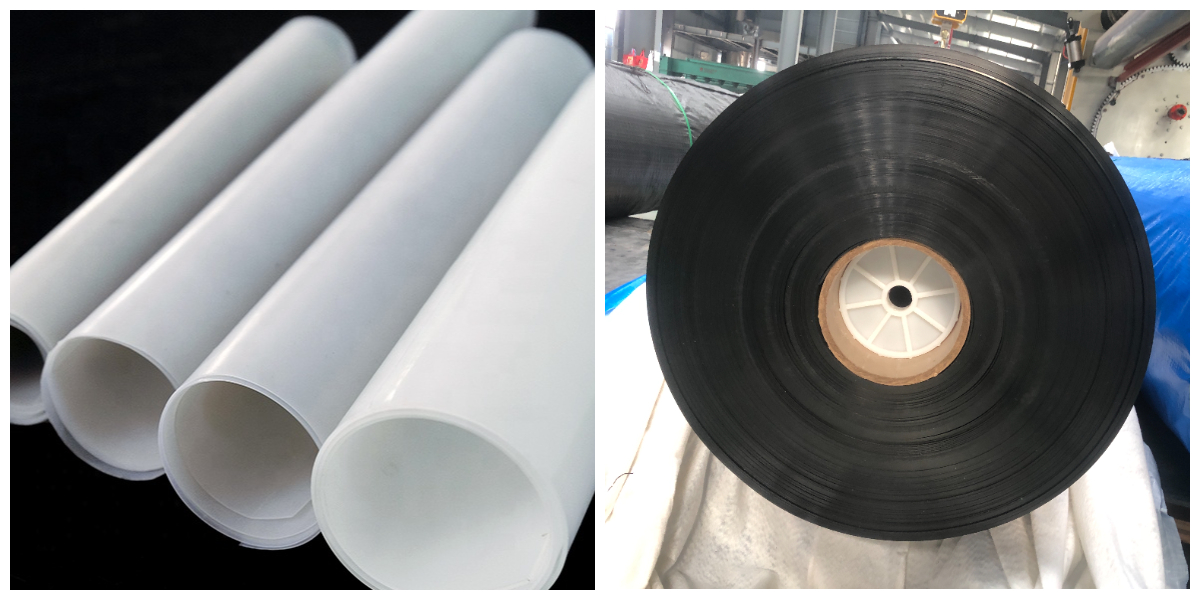

5. Edge Trimming & Winding: Irregular edges are trimmed, and the film is wound into rolls with precise length control (50-100m per roll, adjustable).

6. Quality Inspection: Each batch undergoes tests for thickness uniformity, tensile strength, tear resistance, and impermeability to meet international standards (e.g., ISO, ASTM, JIS).

2. Applications

• Waste management: Landfill liners and caps to prevent leachate leakage, protecting soil and groundwater.

• Hydraulic engineering: Reservoir liners, canal liners, and pond liners for water conservation and seepage control.

• Civil engineering: Tunnel waterproofing, subway station basement liners, and roadbed moisture barriers.

• Agricultural projects: Irrigation canal liners, fish pond liners, and greenhouse soil moisture retention.

• Environmental remediation: Contaminated soil and groundwater remediation barriers.

3. Advantages

• Excellent Impermeability: Near-zero water permeability to effectively block liquid seepage.

• High Flexibility & Toughness: Good elongation at break (≥500%) and resistance to puncture, adapting to uneven terrain and soil settlement.

• Durability: UV-resistant, chemical-resistant (against acids, alkalis, and organic solvents), and non-biodegradable.

• Easy Installation: Lightweight, easy to weld (hot wedge welding or extrusion welding) and lay, reducing construction time and labor costs.

• Cost-Effective: Long service life (15-20 years) with low maintenance requirements, lowering overall project costs.

4. Packaging

• Standard packaging: Woven PP bags with moisture-proof inner lining, each roll weighs 200-1500kg (customizable).

• Roll specifications: Width 4-8m, length 50-100m (adjustable per customer requirements).

• Labeling: Each package is marked with product name, material (LLDPE), thickness, width, length, weight, batch number, and certification logos (e.g., ISO, CE).

• Shipping: Palletized with stretch film wrapping to prevent scratches and moisture damage during container transport; additional protective covers available for long-distance shipping.