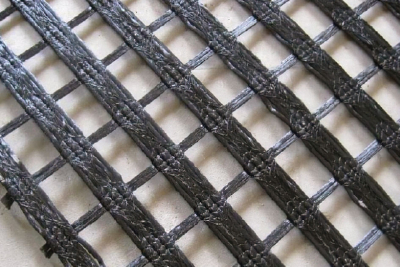

LLDPE Geomembrane Liners Designed

Superior flexibility

UV and chemical resistant

Puncture resistant

Long performance and durability

LLDPE Geomembrane Liners Designed For Waste Containment

Introduction:

The LLDPE Geomembrane is a linear low-density polyethylene liner known for its superior flexibility and strength. It is ideal for applications where a high degree of adaptability is required, such as in agricultural ponds, landfills, and irrigation canals. This material combines excellent tear and puncture resistance with strong chemical resistance, ensuring a reliable barrier in demanding environments. Its lightweight nature makes it easy to handle, reducing installation time and labor costs.

Key Features:

Flexible and Adaptable – LLDPE offers excellent flexibility, making it suitable for uneven surfaces.

Superior Tear Resistance – Provides enhanced protection against punctures and tears.

Excellent Chemical Resistance – Withstands exposure to a wide range of chemicals and environmental elements.

Easy Installation – Lightweight and flexible, making it easy to transport and install.

Application:

Deformation-Sensitive Projects :Landfill closures, mine leaching ponds, and tailings ponds use Geomembrana 2mm or 60 mil HDPE liners (to mitigate settlement deformation).

Complex Structure Anti-Seepage:

Culverts, curved tunnel surfaces, and sewage pipe linings use 30 mil HDPE liners or Geomembrana 40 mil HDPE (due to its high conformability).

Ecologically Sensitive Projects:

Aquaculture ponds (fish/shrimp ponds) use 0.5mm anti-seepage liners or 40 mil HDPE geomembranes (to ensure non-toxicity) and drinking water reservoirs.

Small and Medium-Sized Water Conservancy Seepage Control:

Anti-seepage coatings on the bottom and slopes of small and medium-sized reservoirs, mountain ponds, and irrigation ditches.

Agricultural Facilities Seepage Control:

Moisture-proof layers on greenhouse foundations, integrated water and fertilizer storage tanks, and anti-seepage liners for artificial wetlands.

Municipal Small-Scale Liquid Storage Facilities:

Secondary anti-seepage coatings for rainwater collection tanks and regulating tanks at small sewage treatment plants.

SPECIFICATION:

Test Property | Test Method Unit | Minimum Average Roll Value | |||

1.0mm | 1.5mm | 2.0mm | |||

Thickness(min.ave) ● lowest individual of 10 values | ASTM D 5199 | % | nom-10 | nom-10 | nom-10 |

Formulated Density(min.ave) | ASTM D1505/D792 | g/cc | 0.939 | 0.939 | 0.939 |

Tensile Properties(min.ave) | ASTM D 6693 | ||||

● break strength | kN/m | 27 | 40 | 53 | |

● break elongation | % | 800 | 800 | 800 | |

Tear Resistance(min.ave) | ASTM D 1004 | N | 100 | 150 | 200 |

Puncture Resistance(min.ave) | ASTM D 4833 | N | 250 | 370 | 500 |

2% modulus (max) | ASTM D 5323 | N/mm | 420 | 630 | 840 |

Axi-Symmetric Break resistance Strain (min) | ASTM D 5617 | % | 30 | 30 | 30 |

Carbon Black Content(range) | ASTM D 4218 | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 |

Carbon Black Dispersion | ASTM D 5596 | For 10 different views:9 in Categories 1 or 2 and 1 in Category 3 | |||

Oxidative Induction Time(OIT)(min.ave) (a)Standard OIT (b)High Pressure OIT |

ASTM D 8117 ASTM D 5885 |

min min |

100 400 |

100 400 |

100 400

|

Oven Aging at 85℃ (a)Standard OIT(min.ave)-retained after 90 days (a)High PressureOIT(min.ave)- retained after 90 days

| ASTM D 5721

ASTM D 8117

ASTM D 5885

| %

%

%

|

35

60 |

35 60 |

35 60 |

UV Risistance High Pressure OIT(min.ave)- retained after 1600hrs |

ASTM D 5885 |

% |

35 |

35 |

35 |