PET non woven geobag price

Fabrics produced for the geotextile bags use have improved physical and hydraulic qualities.

The fabric structure's exceptional and the elasticity allows for quick adaption to diverse landforms and field situations.

Special textiles have better permeability than ordinary fabric bags.

High resilience and seam toughness enable constructions to be formed in a stable manner.

Wet haulage, sludge lagoon, sand drying beds, and other manual dewatering processes may all be replaced by geotextile bags.

Geotextile bags' dewatering process is an ecologically beneficial approach to recycle decanted water and water that has been deposited in storm drains or groundwater levels.

Geotextile bags are the most recent invention in preserving our coastlines.

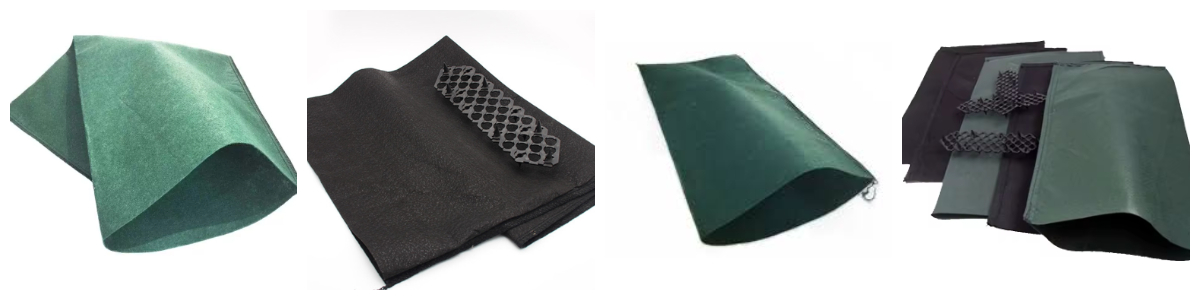

High quality PP/PET non woven geobag price

Description:

Geobag / Geotextile Bag, made of durable geotextile materials, offer versatile solutions for erosion control and environmental projects. They are filled with soil, sand, or gravel for stability. In coastal protection, Geobags create barriers against wave action, preventing erosion and safeguarding ecosystems and infrastructure. For riverbank stabilization, they prevent soil erosion and maintain bank stability, promoting healthy river ecosystems. In land reclamation, Geobags provide efficient containment, forming stable structures for new developments and supporting vegetation growth for green landscapes.

Features of geobag

Quick, Adaptable, and Cost-effective

In general, geotextile bags manufactured by us are filled with in-situ materials, which saves a significant amount of money in terms of supplies, shipping, and deployment. A barrier or support structure may be quickly and simply constructed by stacking the geotextile bags. Geotextile bags by us are available in a variety of colors (black, white, and tan), dimensions, mechanic and hydraulic properties, seam kinds, and attachments such as loops and caps to fulfill a wide range of project engineering demands. As a result, geotextile bags by us are more flexible, efficient, cost-effective, and environmentally beneficial replacement to classic technologies such as cement, steel, rock, or wood.

Great loading capability combined with long-term endurance

Geotextile bags by us are made up of high-quality geo fabrics, a powerful controller loop, and sturdy needle punched. They have a large load bearing capacity, excellent purification process properties, and greater longevity, which include tolerance to UV, abrasive wear, puncture, chemical, and immersive experience abrasion in seawater.

Application of geobag

The following are some of the most typical uses for geotextile bags. In maritime development, geotextile bags are helpful. To safeguard shorelines, protect the toe and slope of sand dunes, reclaim land, and reconstruct beaches, geotextile tubes have been employed.

They may also be used to avoid storm damage, generate sand dune cores, construct breakwaters, and construct islands. Water volumes in the rivers and oceans around the world are rising dramatically as a result of global warming posing a threat to houses and coastlines along the shores.

To safeguard these coastal areas and assets, geotextile bags can be employed. They may be layered to create a water-filtering barrier that safeguards the soil and infrastructure from additional erosion and flood damage.