geomembrane cost

• Superior Friction Performance

• Exceptional Impermeability

• Enhanced Durability

•Seamless Weldability

• Cost-Efficient & Sustainable

1. Introduction

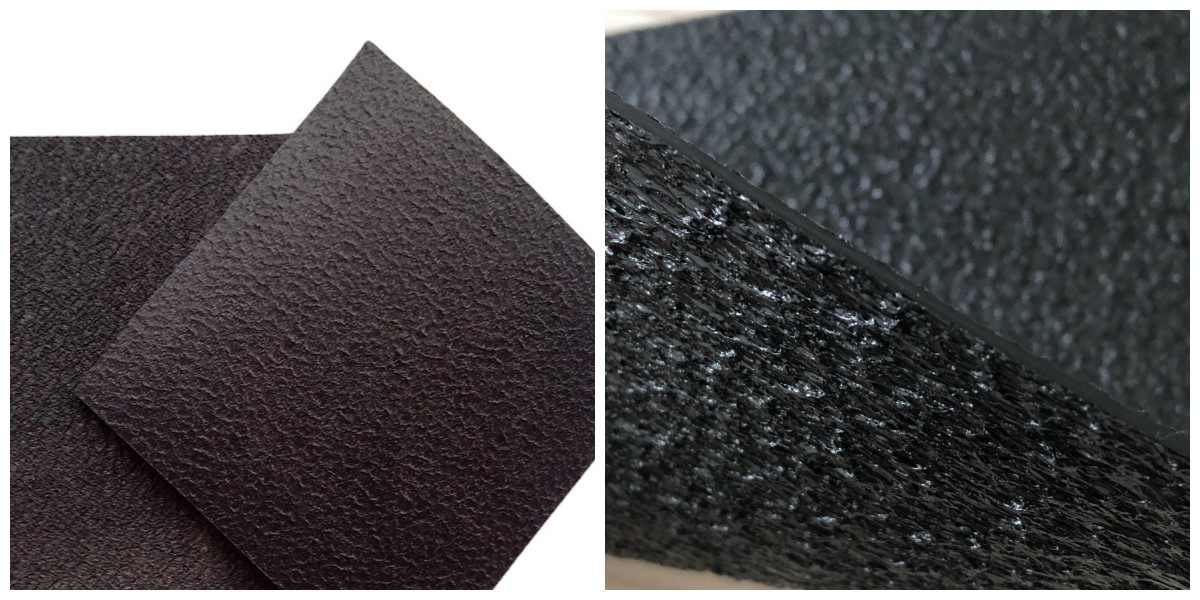

Nitrogen-treated textured HDPE (High-Density Polyethylene) geomembrane is a high-performance impermeable geosynthetic engineered for critical containment applications. It features a smooth HDPE base layer (1.0–3.0 mm thick) with a textured surface—created via nitrogen injection during extrusion—boasting raised protrusions (1–3 mm height) that enhance friction. Made from virgin HDPE resin with UV stabilizers, anti-oxidants, and anti-static additives, it complies with global standards (ASTM D746, EN 13763, ISO 10713) and is trusted by engineers, contractors, and project owners worldwide for its reliability in harsh environments and critical containment scenarios.

2. Core Advantages (Globally Recognized Value)

• Superior Friction Performance: Nitrogen-induced textured surface delivers high friction coefficient (≥0.55 for soil-contact side), preventing slippage in steep slopes (up to 35°) and layered systems—ideal for landfills, dams, and retaining structures.

• Exceptional Impermeability: Ultra-low permeability (≤1×10⁻¹³ m/s) effectively contains leachate, chemicals, and groundwater, meeting strict environmental regulations (EU Landfill Directive, US EPA).

• Enhanced Durability: Virgin HDPE core with additives resists UV radiation, chemical corrosion, and mechanical damage; 50+ year service life in typical applications aligns with long-term infrastructure goals.

• Seamless Weldability: Compatible with hot-air and extrusion welding, forming strong, leak-proof joints (weld strength ≥80% of base material) for large-scale projects.

• Cost-Efficient & Sustainable: Lightweight (3–8 kg/m²) reduces transportation and installation costs; recyclable material aligns with global sustainability initiatives (EU Green Deal, LEED).

3. Key Global Applications

• Environmental Containment: Landfill liners/capping systems (Europe, US, Asia), mine tailing ponds (Australia, South America), and contaminated site remediation—preventing soil and groundwater pollution.

• Water Resources: Reservoir, canal, and irrigation liners (Middle East, North Africa) for water conservation; dam and flood control barriers (Europe, Southeast Asia).

• Civil Infrastructure: Tunnel and subway waterproofing (Tokyo, London, Dubai); road/railway subgrade liners (North America, Europe) to control seepage and stabilize structures.

• Industrial Projects: Chemical storage tank secondary containment (EU/US refineries), oil/gas pipeline bedding (Russian Arctic, Middle East), and renewable energy facility liners (solar farms, biogas digesters).

4. Blow Molding Manufacturing Process (Global Standards-Adherent)

1. Raw Material Sourcing & Preparation: Virgin HDPE resin (EU/US/Middle Eastern suppliers) is blended with UV stabilizers, anti-oxidants, and additives. Rigorous QA ensures material purity and compliance with regional standards.

2. Extrusion & Nitrogen Injection: The mixture is melted (180–220°C) and extruded through an annular die. Nitrogen gas is injected into the molten HDPE bubble via precision nozzles, creating controlled pressure to form the textured surface.

3. Bubble Expansion & Cooling: The nitrogen-inflated bubble is expanded to the desired width (3–8m) using air rings. Water-cooled rollers solidify the HDPE, preserving the textured pattern and ensuring uniform thickness.

4. Slitting & Winding: The cooled geomembrane tube is slit into flat sheets. Computer-controlled winding machines roll the material into standard lengths (50–100m), with tension control to avoid deformation.

5. Quality Control (Third-Party Validated): Testing by SGS/Intertek/Bureau Veritas includes permeability, friction coefficient, tensile strength, weldability, and UV resistance—validating compliance with ASTM/EN/ISO standards. Batch-specific test reports are provided for each shipment.

6. Packaging & Logistics: Rolls are wrapped in UV-resistant, moisture-proof packaging for sea freight. Each roll is labeled with batch numbers, certifications, and specs—ensuring traceability for global projects.