ASTM Standard Geosynthetic Clay Liners

Unique self-healing properties

Bentonite clay swells to seal minor punctures when hydrated.

Excellent slope stability

High internal friction angle for secure slope applications.

High chemical resistance

Provides reliable containment for a wide range of leachates.

Resists differential settlement

Flexible construction accommodates ground movement without cracking.

Efficient all-weather installation

Can be deployed quickly without weather or temperature delays.

Description

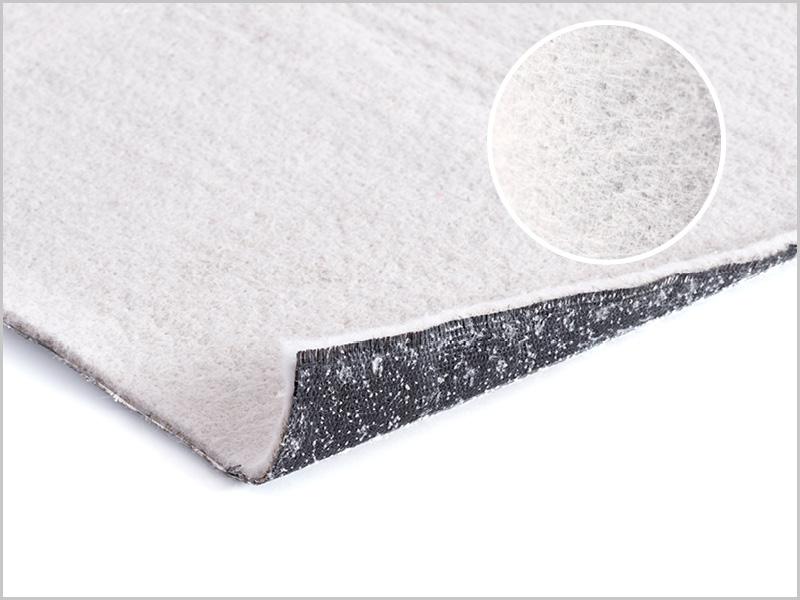

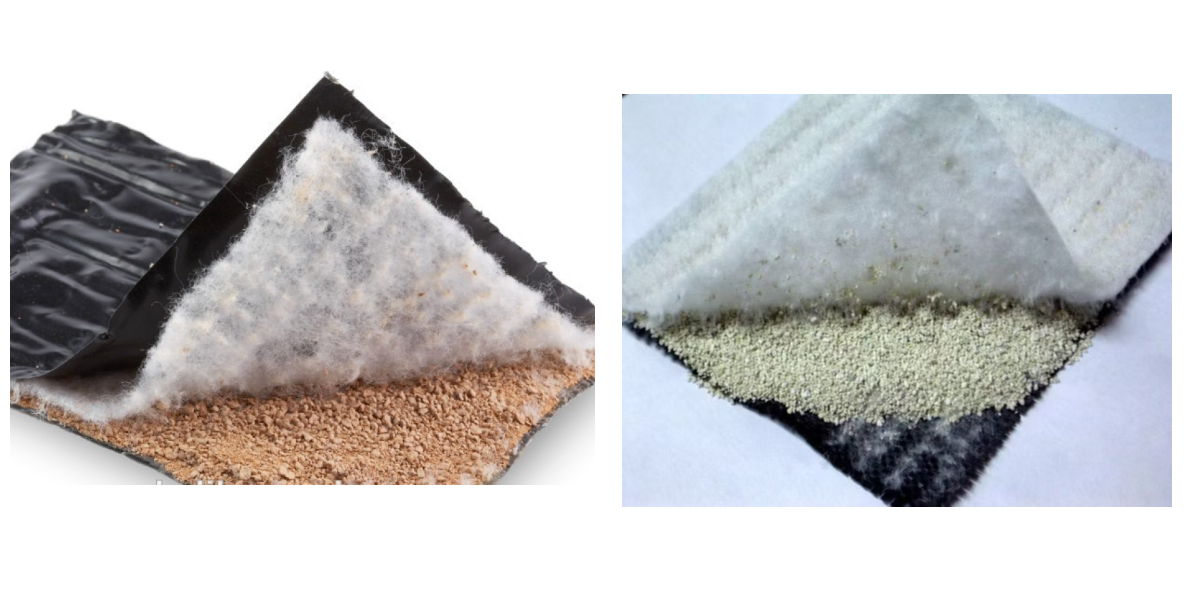

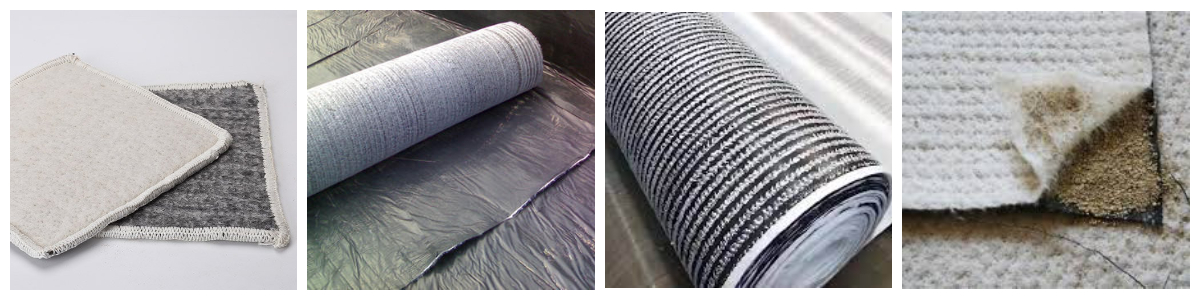

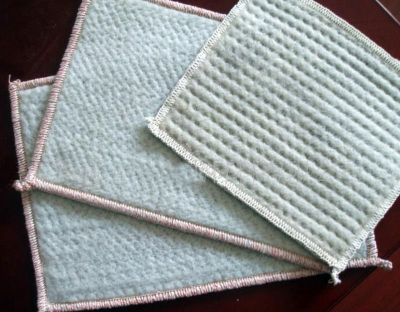

Hongxiang® Geosynthetic Clay Liners (GCLs) are needle-punched reinforced composites which combine two durable geotextile outer layers with a uniform core of natural sodium bentonite clay to form a hydraulic barrier. The sodium bentonite clay utilized in Hongxiang® GCL is a naturally occurring clay mineral that swells as water enters between its clay platelets. When hydrated under confinement, the bentonite swells to form a low permeability clay layer with the equivalent hydraulic protection of several feet of compacted clay. Hongxiang® GCLs are produced by distributing a uniform layer of the sodium bentonite between two geotextiles. Fibers from the non-woven geotextile are then needle-punched through the layer of bentonite and incorporated into the other geotextile (either a woven or a non-woven). This process results in astrong mechanical bond between the fabrics. A proprietary heat treating process - the Thermal Lock process - is then used to modify and more permanently lock the needle-punched fibres into place. Properties include increased internal shear resistance and long term creep resistance.

Benefit

More versatile than compacted clay

Accommodates moderate to steep slopes

Protects against gases, vapors, and liquids

Lower permeability in comparison to clay which swells with water

Hydraulic performance similar to 3ft of compacted clay

Improved stability, creep resistance, and sheer strength

Self-healing without additional textiles

Cost-effective alternative when there is no clay

Simple installation – no welding or seaming is required

What are the advantages of a GCL over compacted clay?

Self-healing and self-seaming - Sodium bentonite is a naturally occurring clay with a high affinity for water. When hydrated, sodium bentonite swells up to 15 times its original volume. This provides the ability to seal around penetrations, self-heal punctures, and self-seam at the overlaps.

Better hydraulic performance - GCLs have a total thickness of less than one inch and provide better hydraulic performance than several feet of compacted clay. A fully hydrated GCL typically has a permeability of 5 x 10-9 cm/sec, approximately 20 times lower than a typical compacted clay liner permeability.

Resistant to varying weather conditions - GCLs are less likely to be impacted by freeze-thaw or desiccation-rewetting cycles. Freeze-thaw cycles frequently cause compacted clay liners to crack and lead to increased leakage. A geosynthetic clay liner provides consistent performance and is not subject to performance decreases resulting from varying moisture content, density, or clay content, like compacted clay liners.

Ease of installation and increased air space - GCLs are an environmentally friendly alternative to clay liners because they require significantly less installation effort than a compacted clay liner. One truckload of GCL is equivalent to 150 truckloads of compacted clay, thereby using up fewer natural resources. When a GCL is used in place of a thicker compacted clay liner it also takes up less air space, which leaves more room for waste.

Applications - Sealing

Landfill caps, closures and base seal

Environmental protection under roads, railways, airports

Dams and dykes

Water containment and pond applications

Structural waterproofing

Secondary containment

Mining applications

Tunnels