Polypropylene non woven geotextile cost

Needle-punched.

Made of 100% polypropylene staple fibers formed into a random network for dimensional stability.

Has excellent chemical compatibility.

Resistant to UV deterioration, rotting, biological degradation, naturally encountered basics and acids.

Easy to install.

Polypropylene non woven geotextile manufacturer

Description:

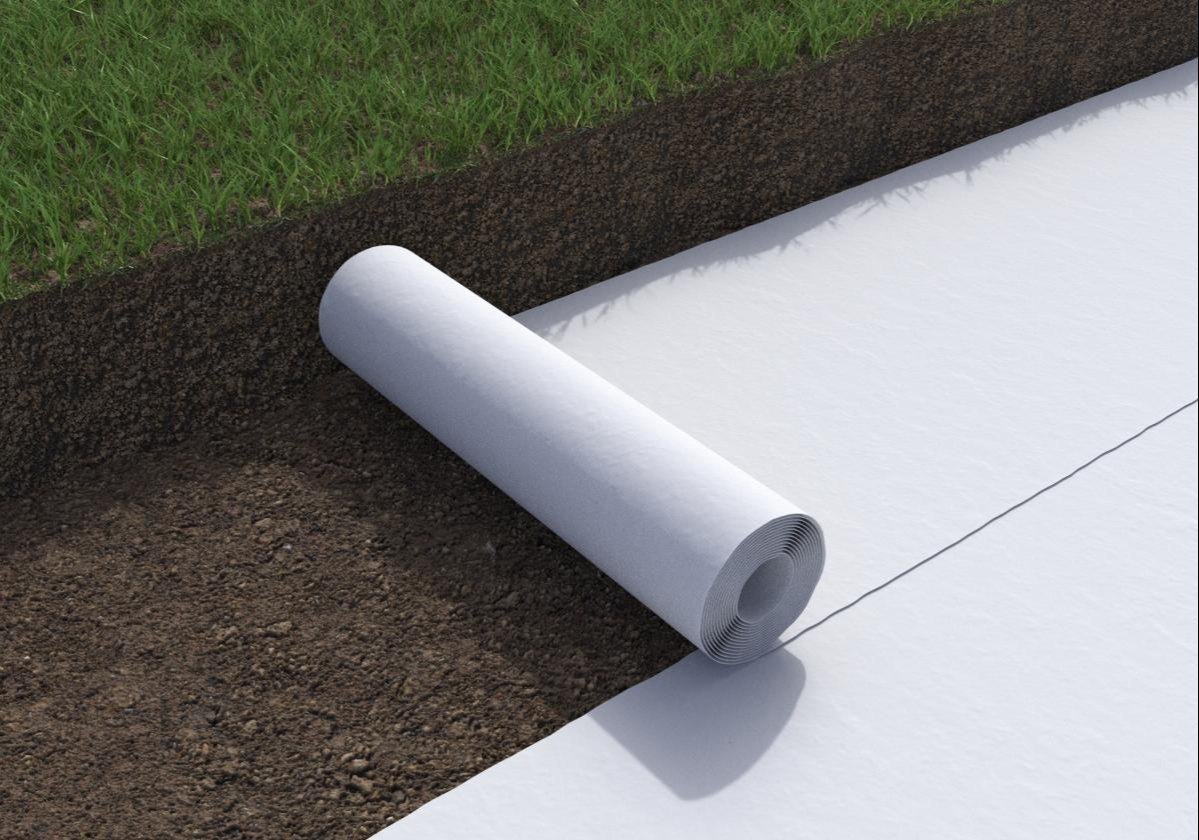

Our nonwoven Geotextiles provide the containment and erosion

control industries with the highest quality geotextiles available.

These needle-punched geotextiles are made of 100%

polypropylene staple fibers, which are formed into a random

network for dimensional stability. They function by restricting soil

particles but allowing liquids and gases to pass through them

easily and are used to improve the performance of environmental

and civil construction projects.

Benefit

Excellent chemical compatibility.

Long-term performance in strength and durability.

Extends road and railway life.

Cost-effective environmental alternative to traditional construction materials.

Prevents banks from soil erosion. Easy to install.

Application:

Nonwoven geotextiles are widely used in civil engineering and construction projects, with essential roles including:

Separation: These materials prevent the mixing of different soil layers, ensuring the stability of roadways and railways.

Filtration: They effectively filter water, allowing it to flow through while retaining soil particles. This is vital in drainage systems and erosion control.

Reinforcement: Nonwoven geotextiles strengthen the soil, enhancing its load-bearing capacity. This is especially valuable in retaining walls and embankments.

Protection: They safeguard geomembranes and other sensitive materials from damage caused by sharp objects or abrasive surfaces. Additionally, they can be used to wrap French drains or in conjunction with other sub-surface drainage solutions.

Specification:

No | Item | Unit | |||||||||

130 | 200 | 300 | 400 | 500 | 600 | 800 | 1000 | ||||

1 | Unit weight | g/m2 | 100(1±5%) | 200(1±6%) | 300(1±6%) | 400(1±6%) | 500(1±6%) | 600(1±6%) | 800(1±6%) | 1000(1±6%) | |

2 | Grab strength | MD | N | ≥450 | ≥900 | ≥1250 | ≥1600 | ≥2000 | ≥2400 | ≥3000 | 3600 |

CD | ≥450 | ≥900 | ≥1250 | ≥1600 | ≥2000 | ≥2400 | ≥3000 | 3600 | |||

3 | Grab elongation | MD | % | 50~90 | 50~100 | ||||||

CD | 50~90 | 50~100 | |||||||||

4 | Tear strength | MD | N | ≥175 | ≥350 | ≥425 | ≥500 | ≥580 | ≥650 | ≥800 | ≥950 |

CD | ≥175 | ≥350 | ≥425 | ≥500 | ≥580 | ≥650 | ≥800 | ≥950 | |||

5 | CBR mullen burst strength | KN | ≥1.25 | ≥2.5 | ≥3.5 | ≥4.3 | ≥5.8 | ≥7.5 | ≥9.5 | ≥12.0 | |

6 | Breaking strength | MD | KN | ≥5.5 | ≥11 | ≥16 | ≥22 | ≥32 | ≥40 | ≥55 | ≥68 |

CD | ≥5.5 | ≥11 | ≥16 | ≥22 | ≥32 | ≥40 | ≥55 | ≥68 | |||

7 | Breaking elongation | MD | % | 40~65 | 50~80 | ||||||

CD | 40~65 | 50~80 | |||||||||

8 | Puncture resistance | N | ≥220 | ≥430 | ≥665 | ≥900 | ≥1200 | ≥1430 | ≥1900 | ≥2350 | |

9 | Thickness | ㎜ | 1.4~1.7 | 1.8~2.2 | 2.4~2.8 | 3.0~3.5 | 3.6~4.0 | 4.0~4.4 | 4.8~5.2 | 5.6~6.0 | |

10 | Peel strength | N/5㎝ | ≥80 | ≥100 | |||||||

11 | Acid and alkali resistance (polypropylene) | % | Breaking strength retention rate ≥90%; Breaking strength retention rate ≥90% | ||||||||

12 | UV resistance strength retention rate | % | ≥80 | ||||||||

13 | Sieve size O90 | ㎜ | ≤0.1 | ||||||||

14 | Vertical Permeanbility Coefficient | ㎝/s | ≤0.2 | ||||||||