geosynthetic clay liner cost

• Superior Impermeability

• Self-Healing Capability

• Eco-Friendly & Sustainable

• Easy Installation & Cost-Effective

• Durability & Versatility

1. Product Introduction

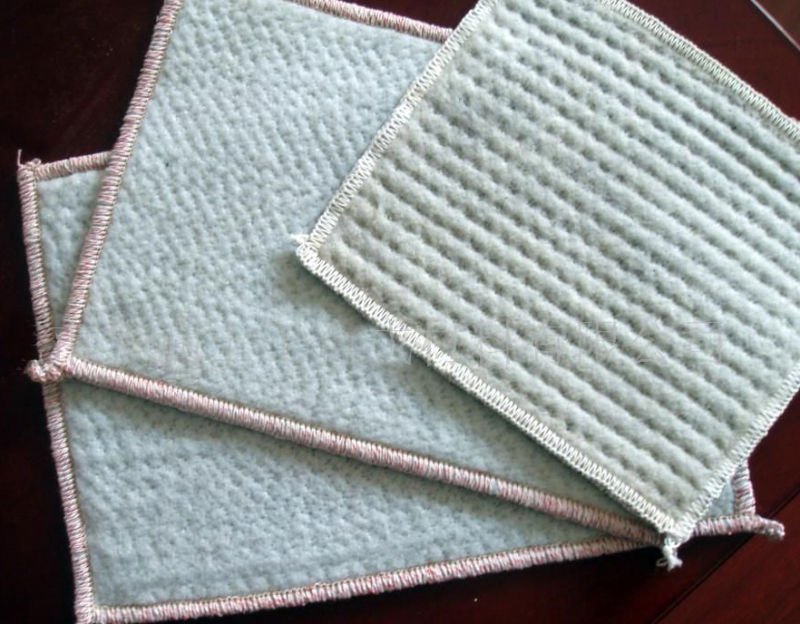

Bentonite Waterproofing Mats (BWM), also known as geosynthetic bentonite clay liners (GCL), are high-performance composite waterproofing materials engineered for environmental and civil engineering projects. Composed of a core layer of natural sodium bentonite (a highly swellable clay mineral), sandwiched between geotextiles (non-woven and woven) and reinforced with needle-punching or stitching, BWMs leverage bentonite’s inherent water-absorbing properties to form a dense, impermeable barrier when activated by moisture. Compliant with international standards such as EN 13968, ASTM D6363, and ISO 10719, they are recognized as a reliable, eco-friendly alternative to traditional waterproofing solutions in global markets.

2. Core Advantages

• Superior Impermeability: When hydrated, bentonite swells up to 15–20 times its dry volume, forming a low-permeability (≤1×10⁻⁹ m/s) barrier that outperforms many synthetic liners in seepage control.

• Self-Healing Capability: Minor punctures or tears automatically seal as bentonite particles migrate to the damaged area, ensuring long-term waterproofing integrity without manual repairs.

• Eco-Friendly & Sustainable: Made from natural, non-toxic bentonite clay, BWMs are chemically inert, recyclable, and compliant with strict environmental regulations (e.g., EU REACH, US EPA) for green projects.

• Easy Installation & Cost-Effective: Lightweight and flexible, they adapt to uneven substrates, reducing on-site labor and equipment needs; no special welding or adhesives are required, cutting installation time and costs.

• Durability & Versatility: Resistant to UV radiation, chemical erosion (mild acids, alkalis), and temperature fluctuations (-20°C to 60°C), ensuring stable performance in harsh outdoor conditions.

3. Key Applications

BWMs are widely adopted across global infrastructure, environmental protection, and construction projects, including:

• Waste Management: Landfills (municipal solid waste, hazardous waste) and leachate collection systems, preventing contaminant leakage into soil and groundwater.

• Water Conservancy: Reservoirs, ponds, canals, and dam cores/linings, enhancing water retention and seepage control in arid and semi-arid regions.

• Civil Engineering: Underground structures (basements, tunnels, subway stations), foundation waterproofing, and cut-off walls for slope stabilization.

• Aquaculture & Agriculture: Fish ponds, shrimp farms, and irrigation channels, reducing water loss and maintaining water quality.

• Environmental Remediation: Contaminated site capping, landfill closure, and mine tailing ponds, isolating pollutants from the surrounding ecosystem.

4. Production Process

1. Raw Material Preparation: Select high-quality sodium bentonite ore, crush, grind, and sieve to achieve a fine powder (200–300 mesh) with controlled moisture content (8–12%) for optimal swelling capacity.

2. Geotextile Lamination: Unwind non-woven geotextile (top layer) and woven geotextile (bottom layer) onto the production line; the non-woven layer enhances bentonite retention, while the woven layer provides structural strength.

3. Bentonite Spreading: Use automated precision equipment to uniformly distribute the bentonite powder between the two geotextile layers, ensuring consistent thickness (2–6 kg/m²) across the mat.

4. Reinforcement & Bonding: Employ needle-punching technology to mechanically interlock the geotextiles and bentonite core, or use stitching with high-strength polyester threads for enhanced cohesion; no chemical adhesives are added to maintain eco-friendliness.

5. Trimming & Rolling: Trim the edges of the composite mat to standard widths (3–6 meters) and lengths (20–50 meters), then roll it onto moisture-proof, tear-resistant cores for storage and transportation.

6. Quality Inspection: Conduct in-line tests for bentonite loading uniformity, tensile strength, and swelling index; issue third-party certification reports (e.g., SGS, Intertek) to verify compliance with international standards before shipment.