Waterproofing Geosynthetic Clay Liner

Effective alternative to compacted clay with much larger installation coverage per day.

Superior tensile strength and self-healing capability solves cracking and leaking problems.

Strong mechanical bond that contributes to extensive shear strength thus provide excellent stability in challenging slope applications.

Simple deployment technique that requires no specialist labor and equipment.

Description

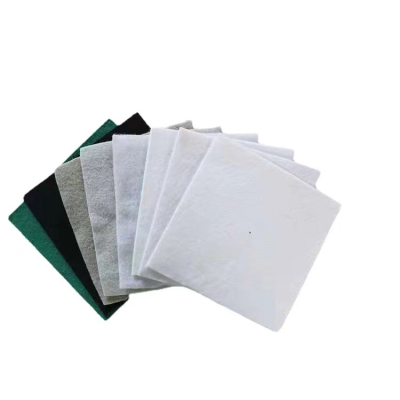

Geosynthetic Clay Liner (GCL), also known as Geocomposite Clay Liner is a geosynthetic erosion control product that consists of two layers of non-woven fabric-like material that incorporates bentonite and needle punched together to form a thick layer of the blanket, primarily used for the lining of landfills. The Geosynthetic Clay Liner functions like a geomembrane which has a relatively low hydraulic conductivity preventing seepage of contaminants and which, has been widely used as the Landfill Lining System that against fluid or containment. Apart from serving as Landfill cap closures or baseliner, the Geocomposite Clay Liner can be configured to meet the specific shear strength and stability to any application including groundwater protection cover, stormwater management ponds, and many ponds, dams, and so forth.

Key Features & Advantages

Excellent impermeability & leakage prevention — upon contact with water, the bentonite core swells to form a dense gel-like barrier, achieving hydraulic conductivity as low as ~1×10⁻⁹–5×10⁻¹¹ m/s.

Self-sealing / self-healing ability — small punctures or overlaps seal automatically as bentonite swells, maintaining barrier integrity and minimizing risk of leakage.

Cherokee Manufacturing

Thin, space-saving, and efficient construction — at only a few millimetres thick (typically ~6–8 mm), GCL delivers comparable or superior performance to metres of compacted clay liner, while saving landfill or containment space.

Easy transport and rapid installation — supplied in rolls, GCL can be quickly deployed on-site, significantly reducing labour, equipment, and installation time versus traditional compacted clay liners.

Good mechanical strength and stability — geotextile layers provide tear resistance, tensile strength and shear strength; needle-punched bonding secures bentonite and resists internal sliding even under load or slope conditions.

Environmentally friendly & cost effective — using natural bentonite clay and geotextiles reduces the need for large volumes of soil, minimizes environmental disturbance, and lowers transport and installation costs.

Typical Applications

GCL is widely used across civil, environmental, and geotechnical engineering projects, including:

Landfill liners and caps — to contain leachate and prevent groundwater contamination.

Mining waste containment — tailings ponds, heap-leach pads, chemical waste ponds, and other mining-related impoundments.

Water containment — reservoirs, canals, ponds, irrigation channels, artificial lakes, and other water storage or conveyance structures.

Waterproofing & sealing for civil/underground structures — tunnels, basements, subgrade liners, wastewater treatment plants, industrial containment areas.

Environmental protection & waste-water control — hazardous waste containment, chemical waste sites, groundwater protection projects.