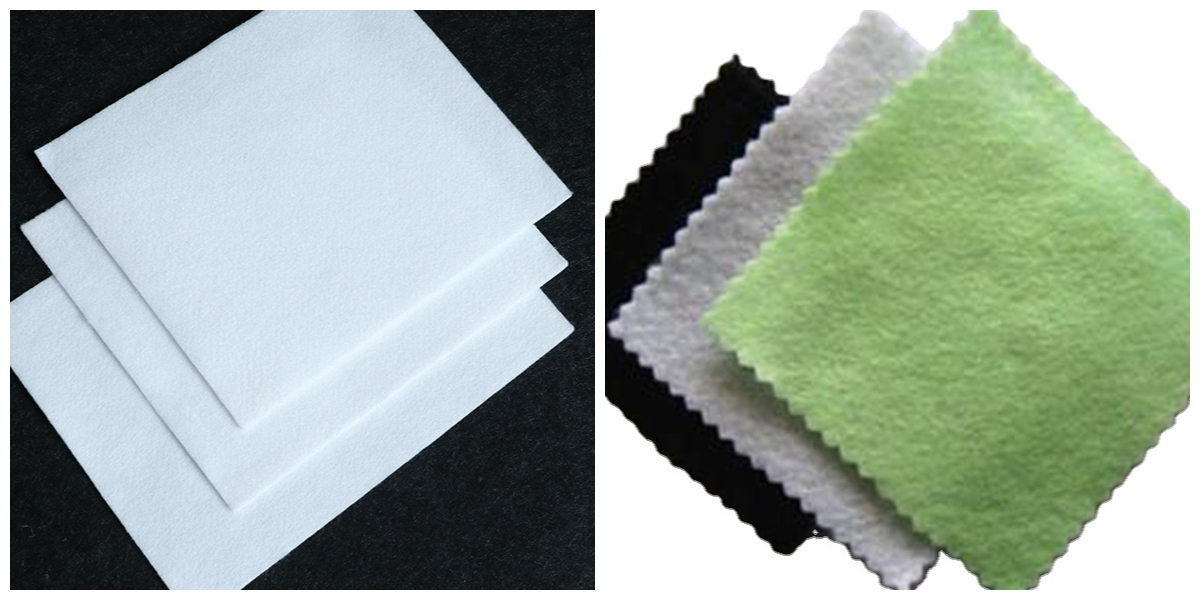

pp geotextile non woven

Key Advantages

Exceptional Durability: Resistant to corrosion, chemicals, and biological degradation.

High Mechanical Strength: Excellent tensile, tear, and puncture resistance.

Cost-Effective: Lower production costs compared to synthetic alternatives

Permeability: Facilitates water drainage while retaining soil particles.

Easy Installation: Lightweight, flexible, and simple to cut/lay.

1. Production Process of Polypropylene Geotextile

1. Raw Material Preparation: High-quality polypropylene (PP) resin is selected as the base material, mixed with functional additives (e.g., UV stabilizers, anti-oxidants) to enhance durability and environmental resistance.

2. Melting & Extrusion: The mixed resin is melted at 200-230℃ in an extruder, then extruded through spinnerets to form continuous PP filaments or short fibers.

3. Web Formation: Filaments/short fibers are laid into a uniform non-woven web via needle-punching (mechanical interlocking) or thermal bonding (heat fusion of fiber intersections) techniques.

4. Calendering & Finishing: The web is calendered to adjust thickness and density, followed by edge trimming, width cutting, and quality inspection (for tensile strength, permeability, and uniformity).

5. Rolling & Packaging: Qualified products are rolled into standard rolls, labeled with technical specifications, and packaged for storage or export.

2. Key Advantages

• Exceptional Durability: Resistant to corrosion, chemicals, and biological degradation (ideal for harsh soil/water environments).

• High Mechanical Strength: Excellent tensile, tear, and puncture resistance to withstand construction loads and soil movement.

• Cost-Effective: Lower production costs compared to synthetic alternatives (e.g., polyester), offering competitive pricing for large-scale projects.

• Permeability: Facilitates water drainage while retaining soil particles, preventing erosion and soil compaction.

• Easy Installation: Lightweight, flexible, and simple to cut/lay, reducing construction time and labor costs.

3. Application Fields

• Civil Engineering: Roadbed stabilization, railway ballast reinforcement, and airport runway base protection.

• Hydraulic Engineering: Riverbank/coastal erosion control, reservoir lining, and drainage systems in irrigation projects.

• Environmental Engineering: Landfill liners (anti-seepage), sewage treatment plant filtration, and mine tailing remediation.

• Construction Projects: Retaining wall reinforcement, basement waterproofing, and green roof drainage layers.

• Agriculture: Soil erosion prevention in farmland, greenhouse floor covering, and irrigation canal lining.

4. Packaging & Export Methods

• Standard Packaging:

◦ Rolled into cylindrical rolls (width: 2-6m, length: 50-100m) with inner plastic film to prevent moisture.

◦ Outer packaging: Woven PP bags or waterproof kraft paper, reinforced with steel strips for transportation safety.

◦ Each roll is labeled with product details (material, tensile strength, batch number, and certification marks like ISO, CE).

• Export Logistics:

◦ Container Shipping: FCL (Full Container Load) for large orders (20ft/40ft containers) or LCL (Less than Container Load) for small batches, with pallets to avoid roll damage.

◦ Documentation: Commercial invoice, packing list, certificate of origin, and quality inspection report (compliant with destination country standards, e.g., ASTM for the US, EN for the EU).

◦ Customized Packaging: Available for OEM orders (e.g., printed company logos, customized roll sizes) to meet client requirements.