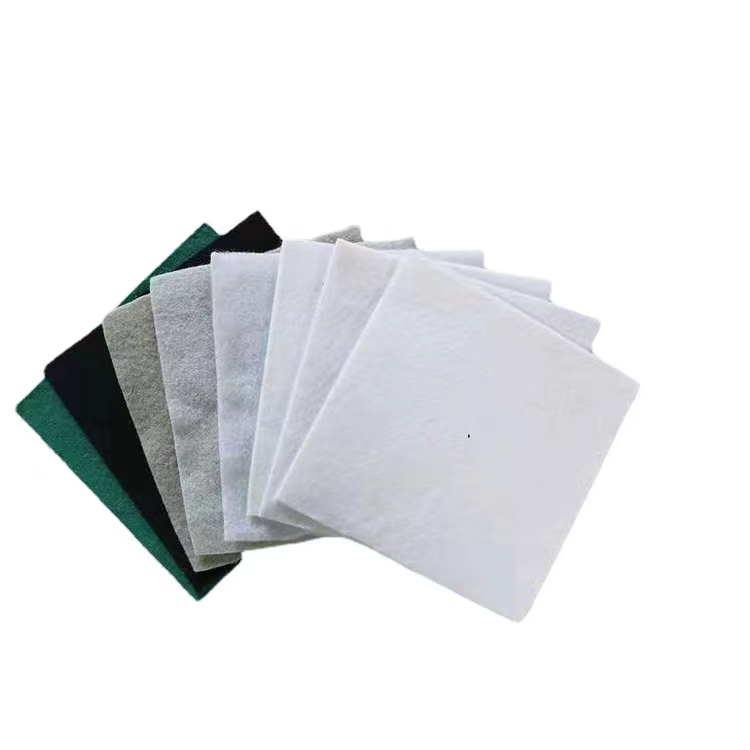

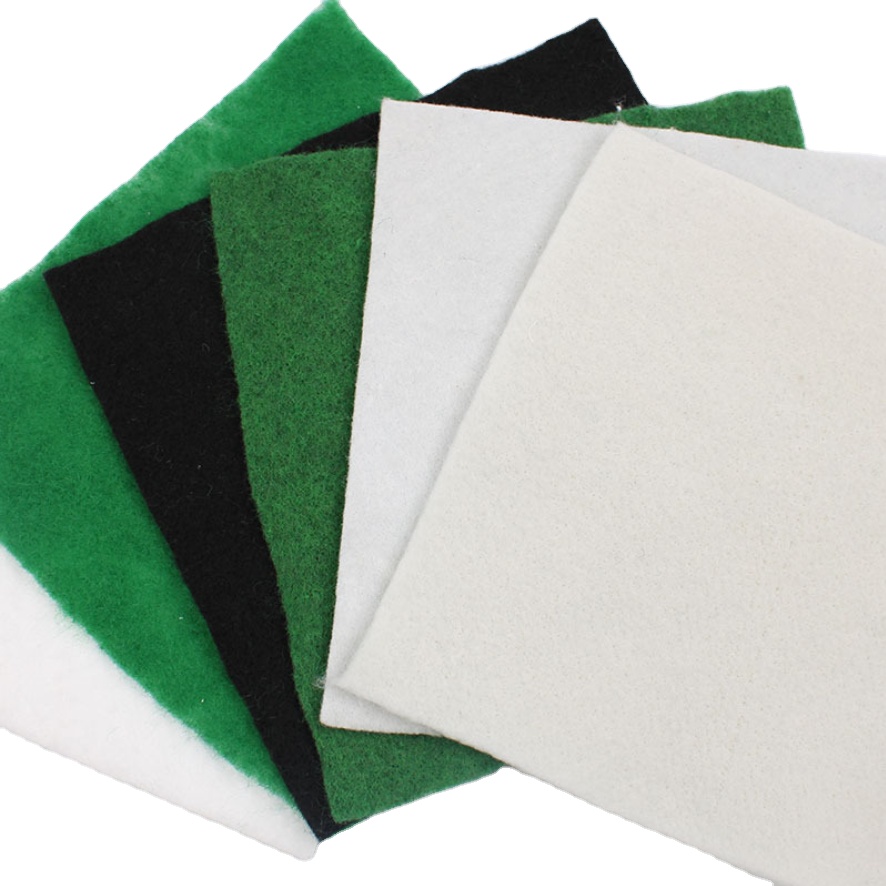

non woven geotextile for drainage

Superior Tensile Strength: Higher breaking strength and modulus than polypropylene alternatives

Exceptional UV Resistance: Maintains performance under prolonged sunlight exposure

Chemical & Biological Stability: Resistant to acids, alkalis, and microbial degradation,

Dimensional Stability: Low shrinkage rate (≤3%) even under high temperature or moisture

Eco-Friendly Option: Recycled PET geotextiles reduce plastic waste, aligning with global sustainability initiatives

1. Raw Material Selection: High-tenacity polyethylene terephthalate (PET) chips (recycled or virgin) are chosen for superior strength, mixed with UV stabilizers and anti-aging additives.

2. Melting & Extrusion: The PET chips are melted at 260-280℃ in a twin-screw extruder, then extruded through spinnerets to form continuous filaments (for woven/non-woven types).

3. Web/Fabric Formation:

◦ Non-woven: Filaments are laid into a web and bonded via needle-punching (mechanical interlocking) or thermal bonding.

◦ Woven: Filaments are woven into a dense fabric using plain, twill, or satin weaves for enhanced structural stability.

4. Finishing Processes: The fabric undergoes heat setting to improve dimensional stability, followed by calendering (for thickness adjustment) and edge sealing to prevent fraying.

5. Quality Control & Rolling: Inspected for tensile strength, elongation, permeability, and UV resistance; qualified products are rolled into standard sizes and packaged.

2. Key Advantages

• Superior Tensile Strength: Higher breaking strength and modulus than polypropylene alternatives, ideal for heavy-load reinforcement projects.

• Exceptional UV Resistance: Maintains performance under prolonged sunlight exposure (suitable for outdoor applications with long service life).

• Chemical & Biological Stability: Resistant to acids, alkalis, and microbial degradation, ensuring durability in harsh soil/water environments.

• Dimensional Stability: Low shrinkage rate (≤3%) even under high temperature or moisture, avoiding deformation during construction.

• Eco-Friendly Option: Recycled PET geotextiles reduce plastic waste, aligning with global sustainability initiatives.

3. Application Fields

• Infrastructure Projects: Highway/railway subgrade reinforcement, bridge approach stabilization, and airport pavement base enhancement.

• Hydraulic & Coastal Engineering: Coastal revetment, riverbank protection, dam filtration layers, and tidal flat reclamation.

• Environmental Protection: Landfill leachate collection systems, mine tailing remediation, and sewage treatment plant filtration.

• Construction & Civil Works: Retaining wall reinforcement, slope stabilization, and basement waterproofing underlays.

• Green Engineering: Vegetation slope protection (combined with geogrids), green roof drainage layers, and wetland restoration.

4. Packaging & Export Methods

• Standard Packaging:

◦ Roll specifications: Width 2-6m, length 50-100m (customizable); inner layer wrapped with moisture-proof plastic film.

◦ Outer packaging: Heavy-duty woven PP bags or waterproof kraft paper, reinforced with steel straps to prevent roll damage during transit.

◦ Labeling: Each roll is marked with product details (material, type, tensile strength, batch number, certification logos like ISO, CE, ASTM).

• Export Logistics:

◦ Container shipping: FCL (20ft/40ft containers) for bulk orders, LCL for small batches; rolls are palletized for easy loading/unloading.

◦ Documentation: Commercial invoice, packing list, certificate of origin, quality inspection report, and compliance certificates (e.g., REACH for EU, FDA for the US).

◦ Customized Services: OEM packaging (printed company logos, custom roll sizes) and pre-shipment inspection coordination to meet client requirements.