bentomat pond liner

Self-Healing Impermeability

High Durability: Resistant to UV radiation, chemical corrosion

Strong Adhesion

Eco-Friendly

Easy Installation

Ⅰ. Production Process of Bentonite Waterproof Blanket (GCL)

1. Raw Material Preparation: High-quality sodium bentonite (montmorillonite content ≥85%) is crushed, sieved, and dried to remove impurities and adjust moisture content (10-15%) for optimal swelling performance.

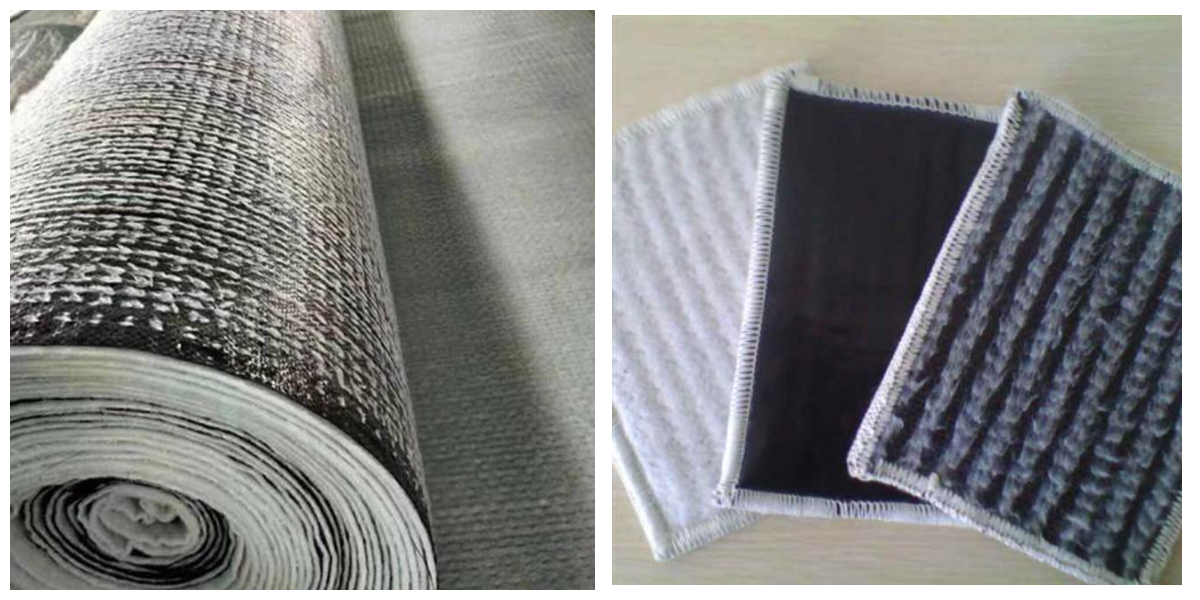

2. Carrier Layer Selection: Two layers of nonwoven geotextile (short-fiber or spunbond PP/PET) are used as top and bottom carriers; optional reinforcement with a woven geotextile layer for enhanced tensile strength.

3. Bentonite Spreading: The processed bentonite is uniformly spread between the two carrier layers via a precision spreading machine, ensuring consistent thickness (2-5kg/m²) across the entire blanket.

4. Needle Punching & Fixing: The three-layer structure (top carrier + bentonite + bottom carrier) is mechanically entangled by needle punching, which secures the bentonite in place and bonds the layers tightly without chemical adhesives.

5. Edge Sealing & Cutting: The blanket is trimmed to standard widths/lengths, with heat-sealed or stitched edges to prevent bentonite leakage; customized sizes are available via slitting.

6. Quality Inspection: Each batch is tested for bentonite content, swelling capacity, impermeability, and tensile strength to comply with international standards (e.g., ISO, ASTM, JIS).

Ⅱ. Applications

• Waste management: Landfill liners/caps, hazardous waste containment, and leachate barrier systems.

• Hydraulic engineering: Reservoir, canal, and pond liners for seepage control; riverbank and dam protection.

• Civil engineering: Tunnel waterproofing, subway station basements, and retaining wall backfill waterproofing.

• Environmental remediation: Contaminated soil and groundwater isolation; wetland restoration projects.

• Agricultural & landscape: Fish pond liners, artificial lake waterproofing, and greenhouse soil moisture retention.

Ⅲ. Advantages

• Self-Healing Impermeability: Bentonite swells 15-20 times its volume when in contact with water, forming a dense, low-permeability gel to seal cracks and gaps automatically.

• High Durability: Resistant to UV radiation, chemical corrosion (acids, alkalis, salts), and biological degradation; stable performance in extreme temperatures (-20℃ to 60℃).

• Strong Adhesion: Bonds tightly with soil and concrete, adapting to terrain settlement without losing waterproof effectiveness.

• Eco-Friendly: Natural bentonite is non-toxic, biodegradable, and environmentally safe; no harmful chemicals released.

• Easy Installation: Lightweight, flexible, and easy to lay without special equipment; reduces construction time and labor costs.

Ⅳ. Packaging

• Standard packaging: Woven PP bags with moisture-proof inner lining, each roll weighs 100-200kg (customizable).

• Roll specifications: Width 2-6m, length 20-50m (adjustable per project requirements).

• Labeling: Each package is marked with product name, bentonite content, grammage, dimensions, weight, batch number, and certification logos (e.g., ISO, CE).

• Shipping: Palletized with stretch film wrapping to prevent moisture absorption and mechanical damage; additional waterproof covers provided for long-distance sea transport.