High Strength PET Filament Geotextile

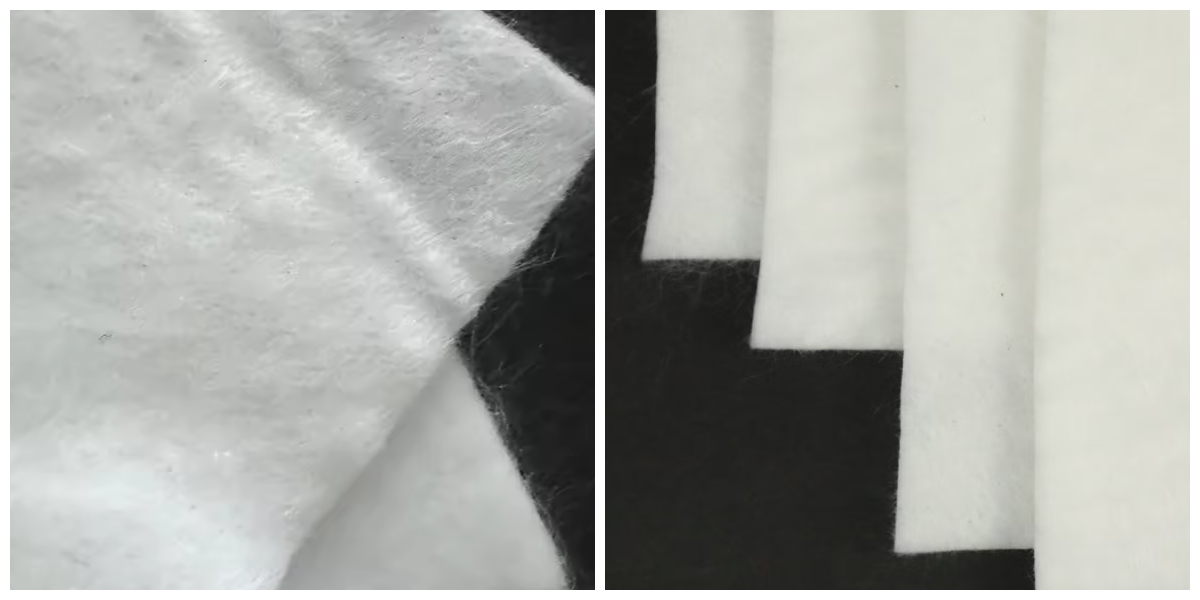

Material: Made from continuous, long polyester (PET) filaments that are bonded together through a needle-punching process.

Structure: Non-woven, meaning the fibers are entangled rather than woven in a traditional grid.

High strength: Exhibits high tensile and puncture resistance, making it suitable for load-bearing applications.

Permeability: High water flow rate allows water to pass through while preventing soil particles from escaping.

Durability: Resistant to chemical degradation, UV radiation, and aging, ensuring a long lifespan.

Dimensional stability: Maintains its shape and structure under various environmental conditions and construction stresses.

Description

PET filament non-woven geotextile fabric is a construction fabric made from continuous polyester fibers that are mechanically entangled, creating a strong, permeable material used for separation, filtration, drainage, and reinforcement in civil engineering projects like roads, railways, and dams. Its key properties include high tensile strength, excellent drainage, chemical and UV resistance, dimensional stability, and ease of installation.

Function

Filtration: Used as a filter layer in drainage systems to prevent soil clogging.

Separation: Isolates different soil or fill materials to prevent mixing, such as between road ballast and foundation soil.

Drainage: Acts as a drainage layer in embankments, retaining walls, and around pipes to collect and remove water from soil.

Reinforcement: Enhances the load-bearing capacity and stability of soil in projects like road construction, airports, and railways.

Erosion control: Protects soil surfaces from erosion, particularly on slopes and riverbanks.

Application:

While the non woven fabric can be used in almost any stabilization,separation or cushioning application, they are most commonly used in areas that also require filtration. The non woven design of the material provides a higher rate of flow through,making it easier for water to pass through the material.Some common uses of the material includes the following:

Road stabilization applications

Roofs

Railway work

Landfill lining

Trenches

Dams

Filtration under rip rap and rocks

Environmental applications

Specification

| Properties | Standard | Unit | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 800 | |

| Tensile Strength | ASTM D 4595 | MD C D | KN/m | 7.7 6.9 | 11.6 10.7 | 14.6 13.4 | 18 16 | 21 19 | 24 22 | 28 25 | 30 27 | 35 32 | 38 35 | 42 38 | 56 52 |

| Tensile Elongation | ASTM D 4595 | MD C D | % | 80 70 | 70 53 | 60 55 | 60 54 | 60 53 | 60 54 | 60 54 | 60 54 | 60 54 | 60 54 | 60 54 | 60 54 |

| Grab Strength | ASTM D 4632 | MD C D | N | 420 378 | 630 580 | 810 729 | 1,070 942 | 1,310 1,192 | 1,520 1,414 | 1,740 1,566 | 1,990 1,791 | 2,500 2,250 | 2,750 2,530 | 3,130 2,817 | 3,490 3,211 |

| Grab Elongation | ASTM D 4632 | MD C D | % | 80 70 | 70 53 | 60 55 | 60 54 | 60 53 | 60 54 | 60 54 | 60 54 | 60 54 | 60 54 | 60 54 | 60 54 |

| Trapezoidal Tear | ASTM D 4533 | MD C D | N | 200 180 | 300 276 | 340 306 | 460 405 | 530 482 | 610 567 | 650 585 | 750 675 | 850 765 | 950 874 | 1,030 927 | 1,300 1,196 |

| CBR Puncture Resistance | ASTM D 6241 | KN(≥) | 1.2 | 1.9 | 2.4 | 3.0 | 4.0 | 4.5 | 5.2 | 5.4 | 6.3 | 7.0 | 7.5 | 10.5 | |

| Puncture Resistance | ASTM D 4833 | N(≥) | 180 | 270 | 350 | 430 | 480 | 560 | 640 | 720 | 800 | 910 | 930 | 1,290 |