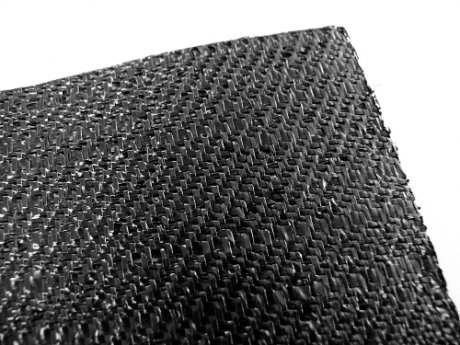

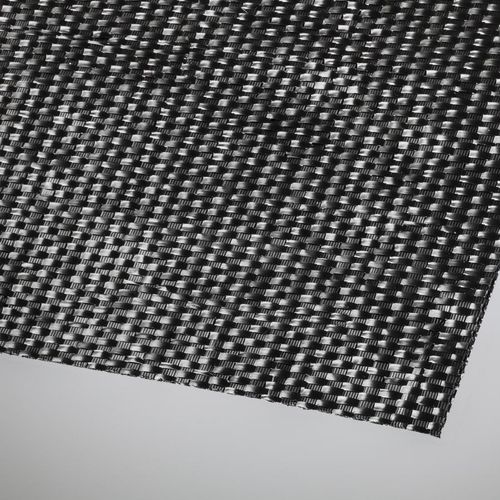

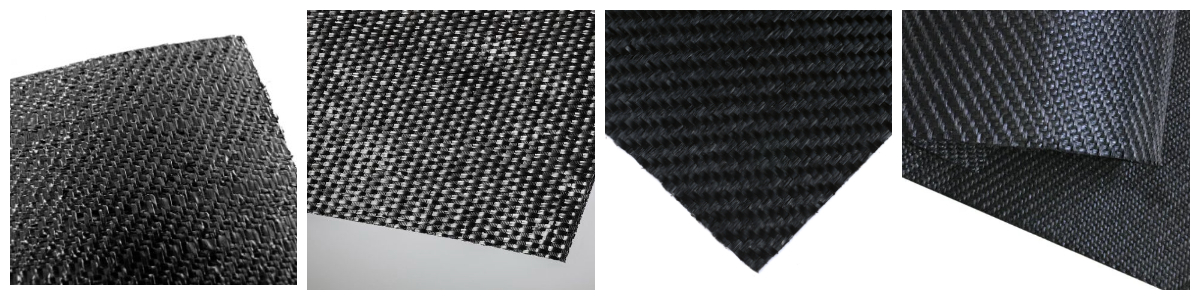

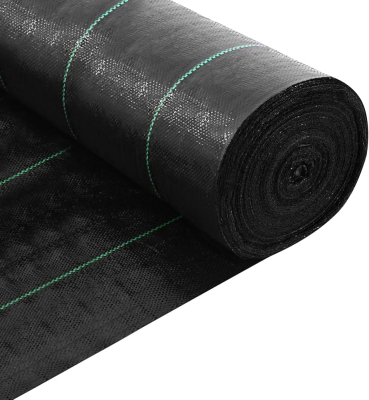

PET woven geotextile fabric

Separation: Prevents the mixing of different soil layers, such as separating a gravel base from a fine-grained subgrade.

Reinforcement: Distributes loads more evenly over a larger area, strengthening weak soils for roads, embankments, and other structures.

Filtration: Allows water to pass through while retaining soil particles, preventing fine sediments from being washed away.

Drainage: Supports drainage systems and helps to prevent the buildup of pore water pressure.

Erosion control: Stabilizes soil on slopes and riverbanks to prevent erosion from wind and water.

Description:

Woven geotextile fabric pet is woven geo fabric made from high tenacity, low elongation material of multifilament polyester yarns to form a stable structure. pet woven geotextile fabric is woven and blended by individual multifilament yarns woven together into a stable fabric structure with a superior combination of mechanical and hydraulic properties. Our pet woven geotextile fabric series has excellent resistance to biological and chemical environments normally found in soils and are stable against short-term exposure to ultraviolet radiation. The woven geotextile fabric is widely used for reinforcement of embankments, retaining structures, steep slopes, linear constructions, landfills, waste deposits, etc.

Pet woven geotextile fabric features

High tensile strength

Low elongation, low creep

High long-term design strength

Creep resistance

Less differential settlement

Cost effective

Ease of installation

Pet woven geotextile fabric applications

Embankment reinforcement

Coastal and side slope production

Sub-grade soft foundation treatment

Railway, road, tunnel, coastal mud flat

Reclamation and environmental project

Specification:

| project | unit | Testing standards | Technical parameters | ||||||||||||

| HK270 | HK370 | HK570 | HK380 /(a) | HK380B | HK580/(a) | HK580B | HK380PPi | HK380PPi-B | HK580PPi | HK580PPi-B | HKH2Oi | ||||

| Breaking strength | Meridian | KN/m | ISO 10319-2015 | 50 | 50 | 70 | 70 | 70 | 90 | 90 | 70 | 70 | 90 | 90 | 90 |

| zonal | 50 | 65 | 70 | 60 | 50 | 80 | 85 | 80 | 90 | 105 | 105 | 90 | |||

| Elongation at break | Meridian | % | ISO 10319-2015 | 10 | 10 | 10.5 | 10 | 10.5 | 10 | 10 | 13 | 13 | 14 | 14 | 13 |

| zonal | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 9 | 9 | 9 | 9 | 9 | |||

| Breaking strength at elongation 2% | Meridian | KN/m | ISO 10319-2015 | 13 | 13 | 15 | 15 | 15 | 18 | 18 | 10.5 | 9.5 | 8 | 7 | 9 |

| Breaking strength at elongation5% | Meridian | KN/m | ISO 10319-2015 | 30 | 30 | 38 | 38 | 38 | 45 | 45 | 30.6 | 25 | 22 | 25 | 28 |

| Mass per unit | g/m2 | GB/T13762-1992 | 225 | 250 | 310 | 280 | 260 | 375 | 380 | 340 | 345 | 420 | 435 | 430 | |

| Static breaking strength(CBR) | KN | GB/T 14800-2010 | 6 | 6.5 | 8 | 8 | 7 | 9 | 10 | 9 | 9 | 10 | 10 | 11 | |

| Equivalent aperture(O90) | mm | GB/T 14799-2005 | 0.42 | 0.45 | 0.48 | 0.48 | 0.33 | 0.45 | 0.4 | 0.48 | 0.48 | 0.47 | 0.48 | 0.45 | |

| permeability(Q50) | L/m2/s | GB/T 15789-2005 | 33 | 28 | 57 | 55 | 54 | 45 | 42 | 58 | 59 | 58 | 52 | 18 | |

| UV resistance(500 hour strong preservation rate) | % | ASTM D4355-2014 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | ||