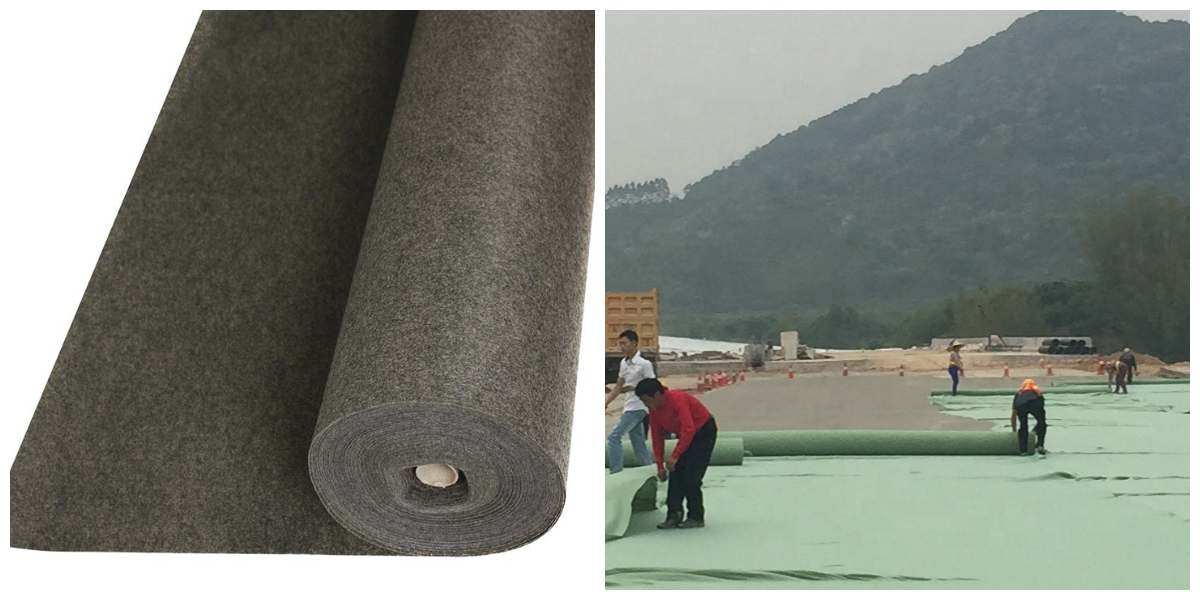

High Strength Woven Geotextile

High Mechanical Strength

Effective Filtration & Drainage

Durability: UV-resistant, chemical-resistant

Easy Installation

Cost-Effective

Raw Material Preparation: High-quality polypropylene (PP) or polyester (PET) chips are selected as base materials, melted and extruded into continuous filaments.

Fiber Formation: Filaments are cut into short fibers (3-6cm) via a cutter, then opened and mixed uniformly to ensure consistent performance.

Carding & Web Formation: Fibers are carded into a loose, uniform web through a carding machine, followed by cross-laying to enhance transverse strength.

Needle Punching: The web is mechanically entangled by thousands of barbed needles (needle punching process), forming a dense, stable structure without chemical binders.

Calendering & Finishing: The fabric is calendered to improve smoothness and density, then cut into standard widths/lengths with edge trimming for dimensional accuracy.

2. Applications

• Road construction: Subgrade separation, drainage, and reinforcement to prevent pavement deformation.

• Hydraulic engineering: Riverbank protection, reservoir lining, and filtration in drainage systems.

• Landfill projects: Anti-seepage support, leachate filtration, and soil stabilization.

• Agricultural & environmental projects: Soil erosion control, vegetation growth promotion, and wetland restoration.

3. Advantages

• High Mechanical Strength: Excellent tensile, tear, and puncture resistance for long-term load-bearing.

• Effective Filtration & Drainage: Porous structure allows water penetration while retaining soil particles.

• Durability: UV-resistant, chemical-resistant (against acids/alkalis), and resistant to biological degradation.

• Easy Installation: Lightweight, flexible, and easy to cut/overlay, reducing construction time and labor costs.

• Cost-Effective: Competitive production costs with long service life, lowering overall project maintenance expenses.

4. Packaging

• Standard packaging: Woven PP bags with moisture-proof inner lining, each roll weighs 100-200kg (customizable).

• Roll specifications: Width 2-6m, length 50-100m (adjustable per customer requirements).

• Labeling: Each package is marked with product name, material, specifications, weight, batch number, and quality certification (e.g., ISO, CE).

• Shipping: Palletized for container transport, with stretch film wrapping to prevent damage during logistics.