drainage geo composite cost

Efficient Drainage

Integrated Functions

Superior Strength

Longevity: UV-resistant, corrosion-resistant

Easy Installation

1.Raw Material Selection: High-density polyethylene (HDPE) or polypropylene (PP) resin is chosen for its durability and chemical resistance, mixed with UV stabilizers and anti-aging additives.

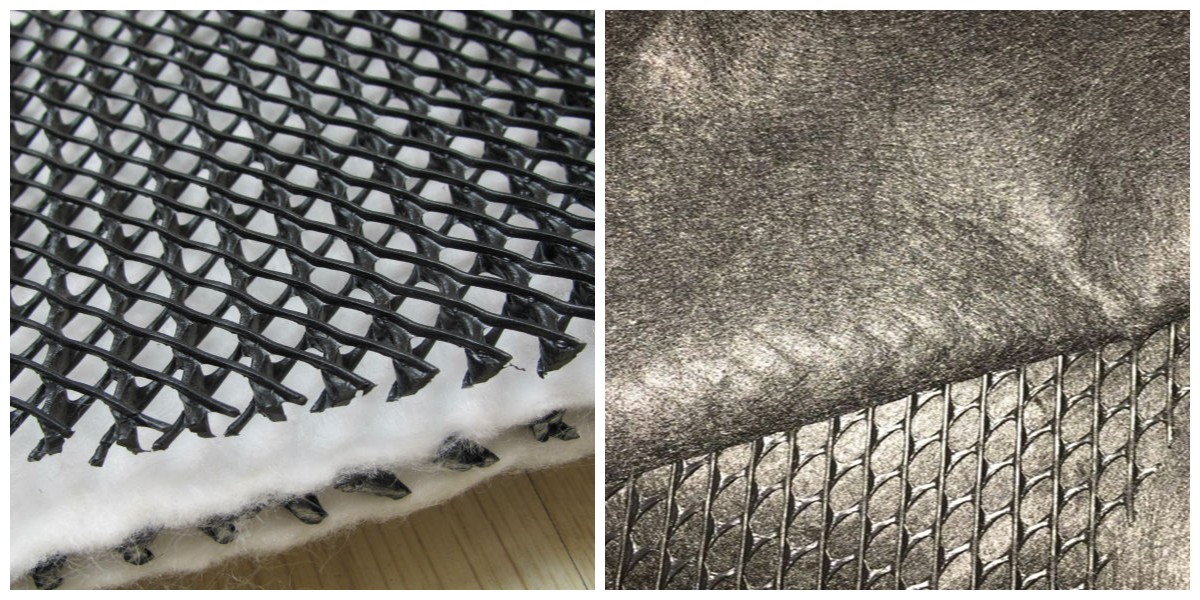

2. Extrusion & Net Formation: Resin is melted and extruded through specialized dies to form two layers of extruded geonet (3D hexagonal or rectangular grid structure) with protruding ribs for drainage channels.

3. Composite Lamination: The geonet core is bonded with nonwoven geotextile (short-fiber or spunbond) on one or both sides via thermal lamination or needle-punching technology, ensuring strong adhesion without chemical binders.

4. Calendering & Sizing: The composite structure is calendered to enhance flatness and structural stability, then cut into standard widths and lengths with precision edge trimming.

5. Quality Inspection: Each batch undergoes tests for tensile strength, drainage capacity, and adhesion strength to meet international standards (e.g., ISO, ASTM, JIS).

2. Applications

• Civil engineering: Road/railway subgrade drainage, airport runway foundation stabilization, and tunnel lining drainage.

• Hydraulic & environmental projects: Landfill leachate collection, riverbank protection, and wetland drainage systems.

• Construction: Basement waterproofing drainage, roof garden drainage, and retaining wall backfill drainage.

• Mining & agriculture: Mine tailings disposal, soil remediation, and agricultural irrigation/drainage.

3. Advantages

• Efficient Drainage: 3D geonet core creates continuous vertical/horizontal channels, enabling rapid water flow (high permeability rate) to prevent waterlogging.

• Integrated Functions: Combines filtration (geotextile layer retains soil particles) and drainage (geonet core) in one product, simplifying construction.

• Superior Strength: High compressive and tensile strength, resistant to deformation under heavy loads or soil pressure.

• Longevity: UV-resistant, corrosion-resistant (against chemicals, salts), and non-biodegradable for long-term service in harsh environments.

• Easy Installation: Lightweight, flexible, and easy to lay/overlay, reducing labor and construction cycle costs.

4. Packaging

• Standard packaging: Woven PP bags with moisture-proof inner lining, each roll weighs 150-300kg (customizable).

• Roll specifications: Width 2-6m, length 50-100m (adjustable per project requirements).

• Labeling: Each package is marked with product name, material, grid thickness, composite layer type, weight, batch number, and certification logos.

• Shipping: Palletized with stretch film wrapping to protect against moisture and mechanical damage during container transport.