PET Geogrid for Pavement Reinforcement

Ensures stability and durability in reinforced structures with high tensile strength at low elongation.

Resistant to soil microorganisms, chemicals, UV radiation, and mechanical damage.

Offers a service life of up to 120 years, providing exceptional durability.

Maintains excellent long-term behavior under sustained loads due to low creep characteristics.

Available in various tensile strengths, making it suitable for diverse applications.

Performs reliably across a wide range of temperatures.

Flexible and easy to install, reducing time and labor costs.

Description:

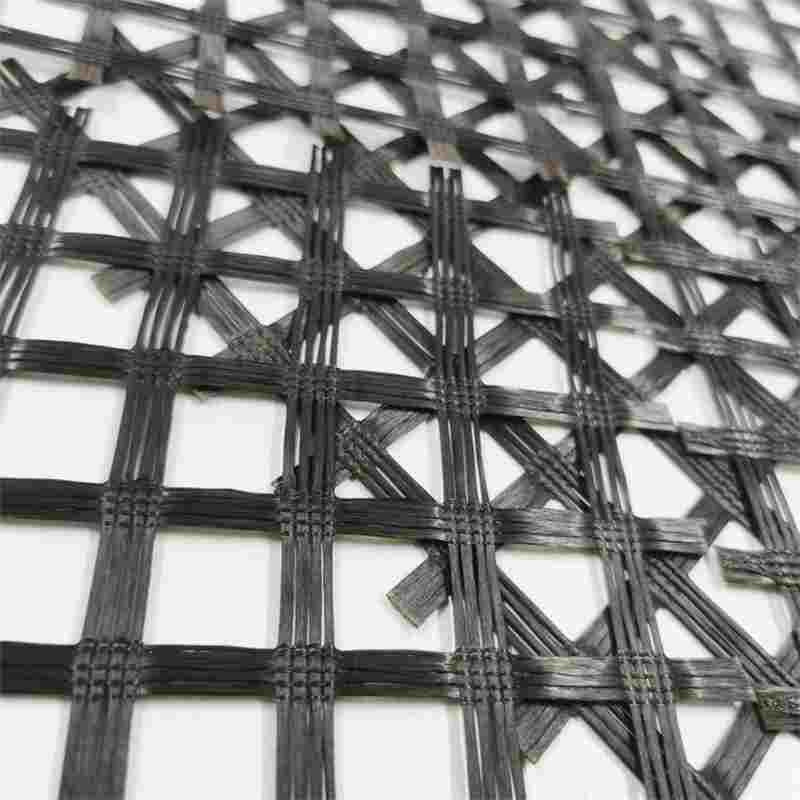

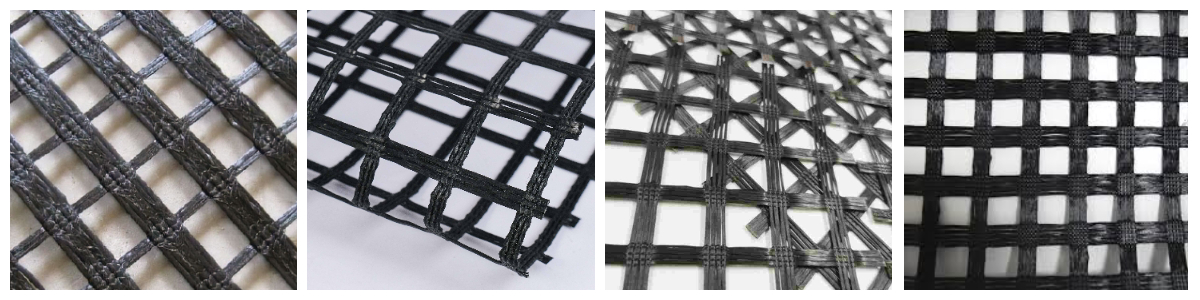

Polyester (PET) geogrid is composed of high molecular weight, high tenacity polyester multifilament yarns are woven in tension and finished with a PVC coating. PET geogrids are inert to biological degradation and resistant to naturally encountered chemicals, alkalis, and acids.

PET geogrid is used as soil reinforcement in MSE structures such as segmental retaining walls, precast modular block walls, wire faced walls, geosynthetic wrapped faced walls and steepened slopes. PET can also be used in MSE stabilized platforms for voids bridging, embankments on soft soils, landfill veneer stability, reducing differential settlement and for foundation seismic stability.

Benefit

Improves the foundation’s load-bearing capacity and stability, ensuring a more reliable and robust structure.

Suitable for various environmental soils with its high strength and low creep characteristics, ensuring long-term performance.

Speeds up construction by minimizing site preparation and installation times, allowing for quicker project completion.

Reduces aggregate layer thickness, leading to less excavation and lower costs while supporting sustainable practices.

Increases the durability of roads and infrastructure, leading to reduced long-term maintenance costs and a safer, proven construction method.

Properties of polyester geogrids:

Tensile strength: Thousands of tests have been conducted, and the results for tensile strength are typically from 85 MPa to over 200 MPa, depending on the design and manufacturing of a different polyester geogrid. StrataGrid™ has tensile strengths up to 800 kN, and are truly exceptional and ensure reliable service under the most difficult conditions.

Modulus of elasticity: The modulus of elasticity for polyester geogrids will lie between 2.76 and 4.14 GPa, which enables it to deform elastically without permanent damage under any level of stress.

Creep resistance: Polyester geogrids are designed to be resistant to creep, which is a time-dependent deformation caused by constant load. Accelerated creep tests show that these geogrids will retain their structural integrity over very long periods and are thus suitable for use in long-term applications in civil engineering.

Chemical resistance: Generally, polyester is a material which has excellent resistance to a wide range of chemicals, thus improving the durability of geogrids under hostile circumstances, such as one finds in landfill applications and road construction.

UV resistance: A protective polymer coating is treated on many polyester geogrids to enhance its resistance to ultraviolet radiation for its longevity under sunlight. Strata Geosystems’ StrataGrid features a company-developed, UV-stabilised coating compound that offers enhanced durability against environmental factors.

Application:

Road construction: They are generally put in sub-base applications in paved and unpaved roads, which can reduce asphalt thickness and distribute loads more effectively.

Soil stabilization: Geogrids provide structural integrity to slopes, embankments, and retaining walls by locking into the particles of soil, thus preventing erosion.

Erosion control: Polyester geogrids offer a framework for vegetation growth in areas susceptible to soil erosion, thereby helping to bind the soil together.

Rehabilitation of pavements: Increasingly, polyester geogrids are applied in rehabilitation works on already existing pavement structures, offering additional support to the latter and eventually extending the life of the roadways.

Landfill liners: They can be used for reinforcing landfill applications in liner systems, guaranteeing stability and preventing contamination.