Non woven membrane

High tensile strength and tearing strength

Excellent seepage control, seepage prevention and moisture proof performance

Excellent chemical resistance

High strength, anti puncture

High friction coefficient, excellent wear resistance

Excellent UV resistance

Stable low temperature resistance to brittleness

Anti-aging and anticorrosion

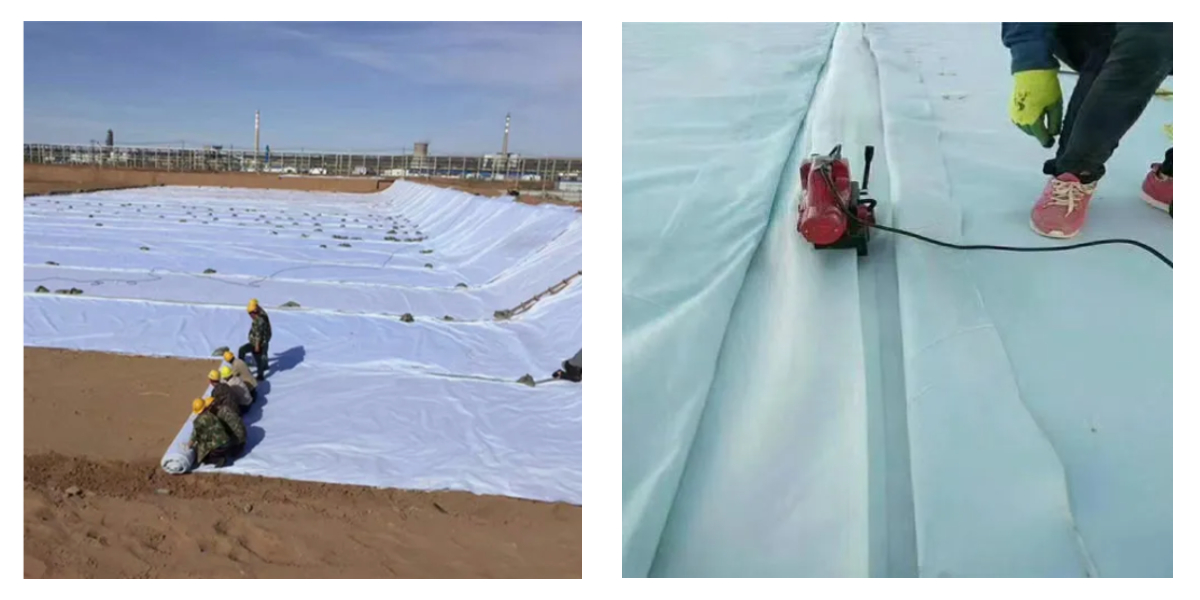

Easy to deploy efficiently

Cost saving

Composite Geomembrane Liner provides the advantages of both geotextiles and geomembranes. The geotextile layer increases essential tensile strength and the geomembranes

provides excellent impermeable, leak, moisture proof and tear and puncture resistance.The main role a composite geomembrane liner has for a municipal solid waste system for

landfills is that is reduces the amount of leakage through small seep holes that sometimes form in the Geomembrane part of the geocomposite liner. Our composite geomembrane

liner is widely used for landfills, waste water treatment, roads construction, aquaculture, landscape and agriculture, etc

Composite Geomembrane Liner is made by heat-bonding nonwoven or woven geotextile combined with HDPE geomembranes by calendaring processing technology. composite

geomembrane liner is automatically formed by pressing one or two geotextile layer to the geomembrane layer in the continuous far infrared ray heating oven, polymer and anti-aging

materials are added in the production process at the same time, so it can be used in unconventional temperature environment.

The composite geomembrane liner provides the advantages of both geotextiles and geomembranes. The geotextile layer increases essential tensile strength and the geomembranes

provides excellent impermeable, leak, moisture proof and tear and puncture resistance. Our composite geomembrane liner are widely used for landfills, waste water treatment, roads construction, aquaculture, landscape and agriculture, etc.