Plastic geogrid

Features:

1. Increase the bearing capacity of the roadbed and foundation and prolong their service life.

2. Prevent road surface and foundation from sinking or flawing, keep clean and beautiful ground surface.

3. Convenient construction saves time and labor, reduce mounting time and decrease maintenance expense.

4. Prevent culverts from flawing.

5. Enhance earth slope and prevent water loss and soil erosion.

6. Decrease underlayer thickness and save manufacturing cost.

7. Enhance the stability of side slope turf net patch to improve greening.

8. Replace wire netting used in mine as intermediate ceiling netting.

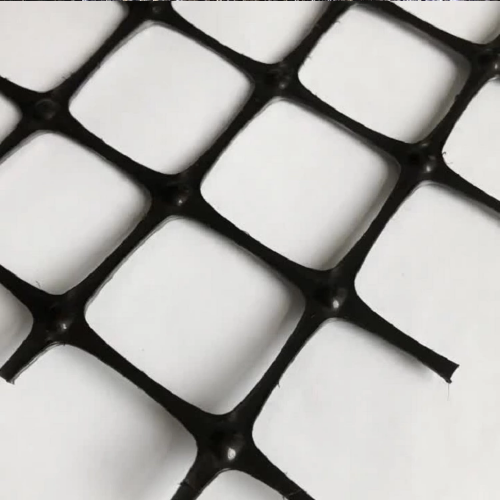

Biaxial geogrid is made of high molecular polymer through extrusion, forming and punching before longitudinal and lateral stretching. This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforcement material.

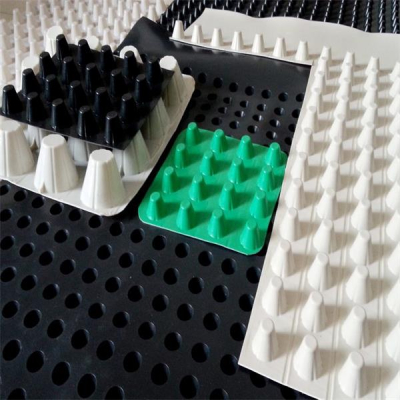

1. Definition of geogrid: with polypropylene, polyvinyl chloride and other polymer by thermoplastic or molding of two-dimensional grid or with a certain height of three-dimensional grid screen, when used as civil engineering, called geogrid.

2. Plastic geogrid is a square or rectangular polymer mesh, according to the different stretching direction of the two kinds of unidirectional stretching and two-directional stretching. It is punched on an extruded polymer plate (mostly polypropylene or high-density polyethylene), followed by directional stretching under heating conditions. The unidirectional stretching grille is stretched only along the length of the plate, while the bidirectional tensile grille is continued to stretch the unidirectional stretching grille in the direction vertical to its length

3. Two-way geogrid/Bidirectional geogrid Bidirectional geogrid is made of polymer through extrusion, plate, punching process and then longitudinal, transverse stretching. The material has a large tensile strength in longitudinal and transverse, and this structure in soil can also provide a more effective force bearing and diffusion, adapted to large areas of permanently bearing foundations

4.The unidirectional geogrid is made of polymer through extrusion into a thin sheet and then flush the regular hole net, and then longitudinal stretch. In this process, the polymer turns into a directional linear state and forms a long elliptical mesh integrity structure with uniform distribution and high node strength. This structure has a very high tensile embedding and tensile modulus, especially our products have a high level of early (elongation in 2% -5%) tensile strength and tensile modulus. The soil provides the ideal force bearing and diffusion. The product has high tensile strength (> 150 Mpa), is suitable for various soil, and is a widely used reinforcement material.

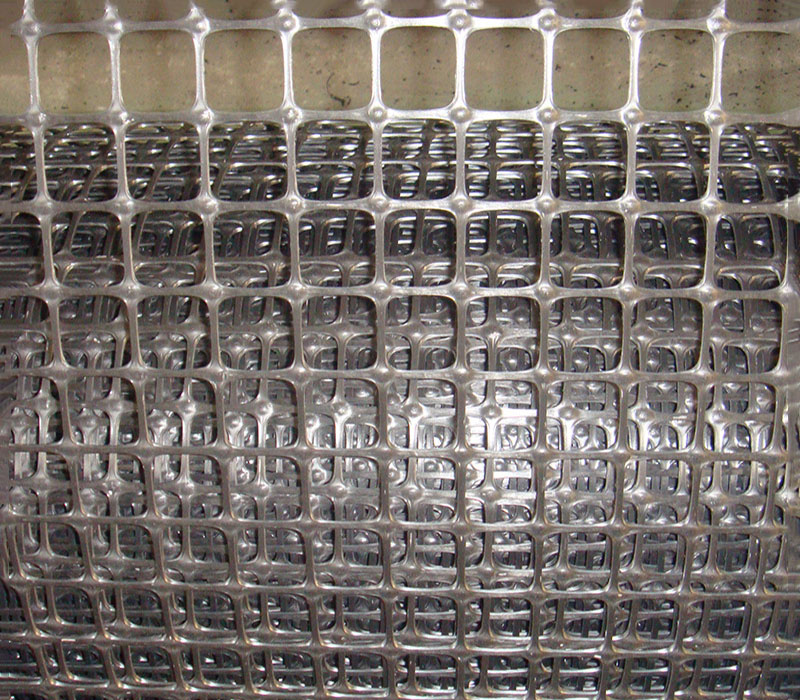

5.Steel-plastic geogrid with high strength steel wire (or other fibers), after special treatment, and polyethylene (PE), and add other additives, through extrusion to make it into a composite high strength tensile belt, and the surface has rough compaction grain, is a high strength reinforced soil belt. From this single belt, through the vertical and horizontal according to a certain spacing preparation or sandwich arrangement, using the special reinforced bonding welding technology welding its junction and molding, is reinforced geogrid.

6.Glass fiber geogrid is a mesh structure material made of glass fiber with certain weaving process. In order to protect the glass fiber and improve the overall performance, it is a geotechnical composite material made by special coating and compound treatment process. The main components of glass fiber are: silicon oxide, inorganic material, with extremely stable physical and chemical performance, high strength, high modulus, excellent cold resistance, no long-term creep; good thermal stability; mesh structure makes aggregate lock and limit; improve the bearing capacity of asphalt mixture. Because of the special surface coated with modified asphalt, it has the composite performance of two weights, which greatly improves the wear resistance and shear ability of geogrid.